| Precision Positioning Crane in Aerospace Industry

| Want to know more about Precision Positioning Crane in Aerospace Industry?

KUNFENG are experienced in supplying lifting gear to those high requirement industries. The aerospace sector demands heavy lifting, delicate handling, and precise positioning.

KUNFENG are experienced in supplying lifting gear to those high requirement industries. The aerospace sector demands heavy lifting, delicate handling, and precise positioning.

Our new belt hoist and clean room cranes are great for controlled environment. Firstly, electric hoist for clean room use should be coordinated with ISO 14644 standards. For the stringent industry, like in semiconductor industry, biotechnology industry, class 10,000 (ISO 7) is the least requirement, which demands production conditions can be achieved in cleanrooms with non-unidirectional airflow.

For the aerospace product manufacturing, medical device manufacturing, electronics manufacturing, Class 1,000 (ISO 6) cleanrooms are a frequently used classification of cleanrooms than class100. And the maximum of 10,000 airborne particles below 0.5 micrometers is permitted per cubic foot.

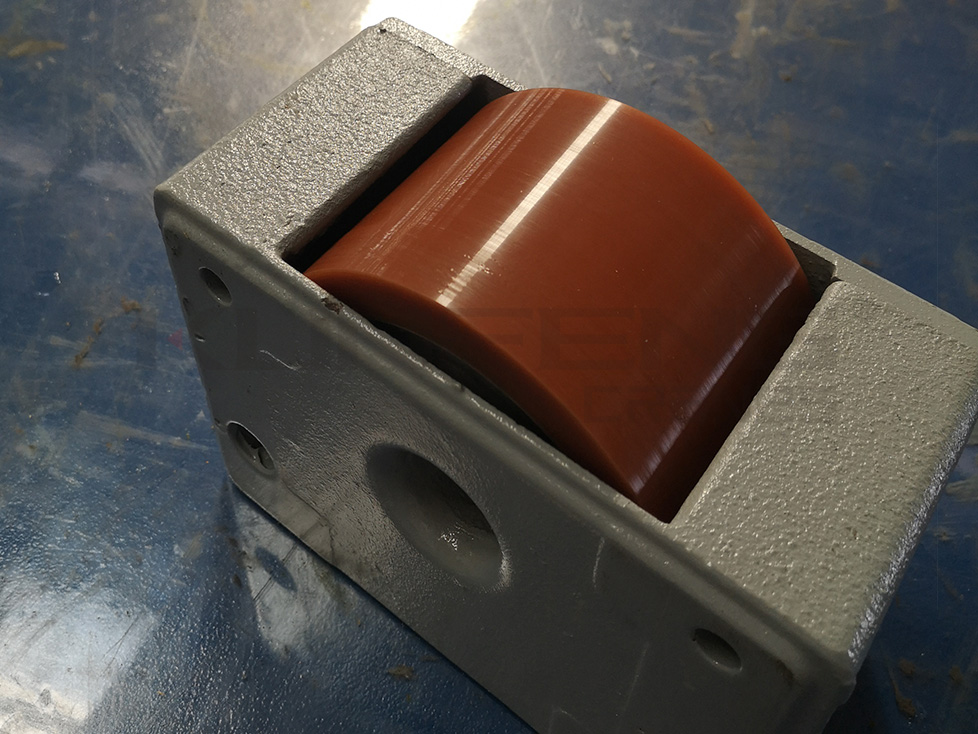

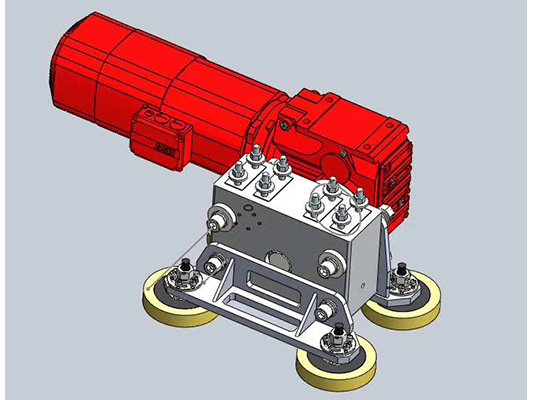

Apart from the cleanness requirement, Precision in positioning is another requirement that KUNFENG CRANES helps to provide. Designed with normal speed and slow lifting speed, positioning accuracy of our cleanroom cranes can be controlled within 0.1mm. The control systems ensure that large parts are lifted smoothly and precisely, eliminating any twisting of the load.

In addition, two hoists also can work in fixed ratio together, one master sender controls both hoists. If one hoist stops, the other stops as well, so there is no possibility that one would continue on its own—which could have catastrophic results. We do systems like that more or less regularly.

Following is parameter for cleanroom crane with belt hoist:

Capacity: 6+6 t

Span: 10.8 m

Lifting height: 4.85 m

Lifting speed: 0.1-3.8 m/min

Crane speed: 0.25-10 m/min

Trolley speed: 0.25-10 m/min

Working level: A4

KUNFENG CRANES designed a top-running double-girder crane with a 12t capacity, with micro speed movements to provide greater control over movement during assembly.

It also featured clean room features. These included self-locking stainless steel fasteners to prevent the loosening of bolts, walkways equipped with kick plates to capture falling debris, and runway conductor bars enclosed in a plastic housing. Special coatings were applied to prevent corrosion.

Double girder cleanroom crane is used not only for manufacturing but for other sensitive hoisting applications such as telescope arrangement, lens management, and spacecraft maintenance.

Contact KUNFENG CRANES to get customized clean room lifting solution.