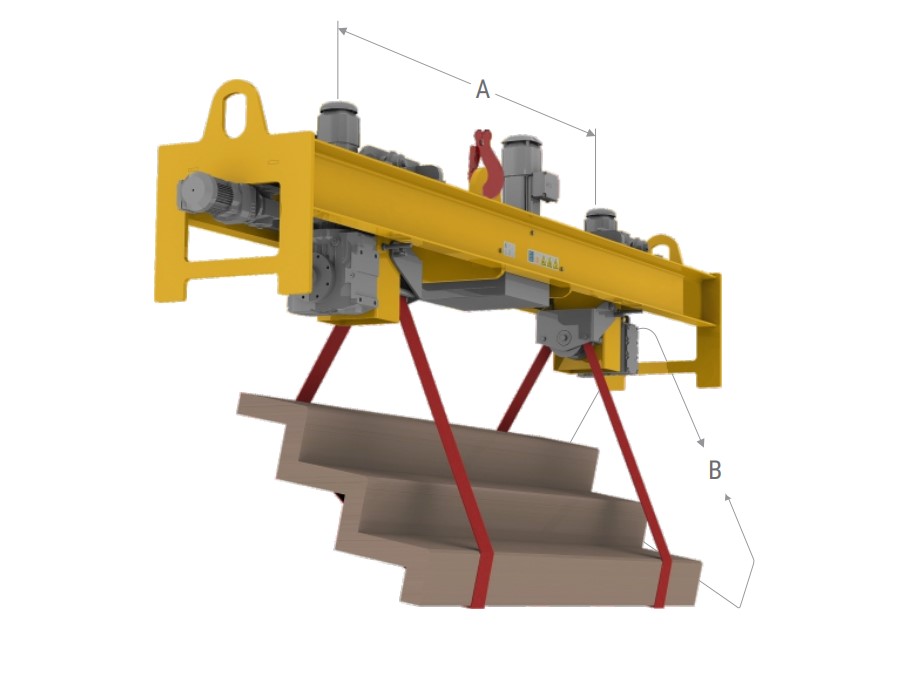

| A device for flipping the main beam of a crane

When making the main beam of the crane, the steel structure needs to be welded in all directions, and the omni-directional welding must turn the main beam at least four times or more.

CATEGORY:

CREATED:

Apr 02, 2022

A device for flipping the main beam of a crane.

The main beam of the crane is a steel structure with an outer frame similar to a rectangle. When making the main beam of the crane, the steel structure needs to be welded in all directions, and the omni-directional welding must turn the main beam at least four times or more. However, since the mass of a single main beam of the crane is 20-60 tons, the length is in the range of 20-40 meters, and the section height is in the range of 1.6-3 meters, so the overturning of such a heavy main beam is very difficult.

In the prior art, the main girder is turned over mainly by using two bridge cranes and hoisting one end of the main girder through wire ropes, so that the main girder is gradually erected. Although this method of flipping the main beam is relatively simple, in the process of flipping the main beam, since the center of gravity of the main beam can generate considerable inertia during the offset process, this inertia can easily cause the wire rope binding the main beam to be pulled. In addition, when the main beam is flipped on the ground,

Because of the strong vibration force generated by the mass assembly, this vibration force will affect various process parameters of the main beam, and even lead to the fracture of the weld joint.