| Overview of polyurethane material bending stiffener origin China

The overview of polyurethane material bending stiffener.

CATEGORY:

CREATED:

Oct 26, 2020

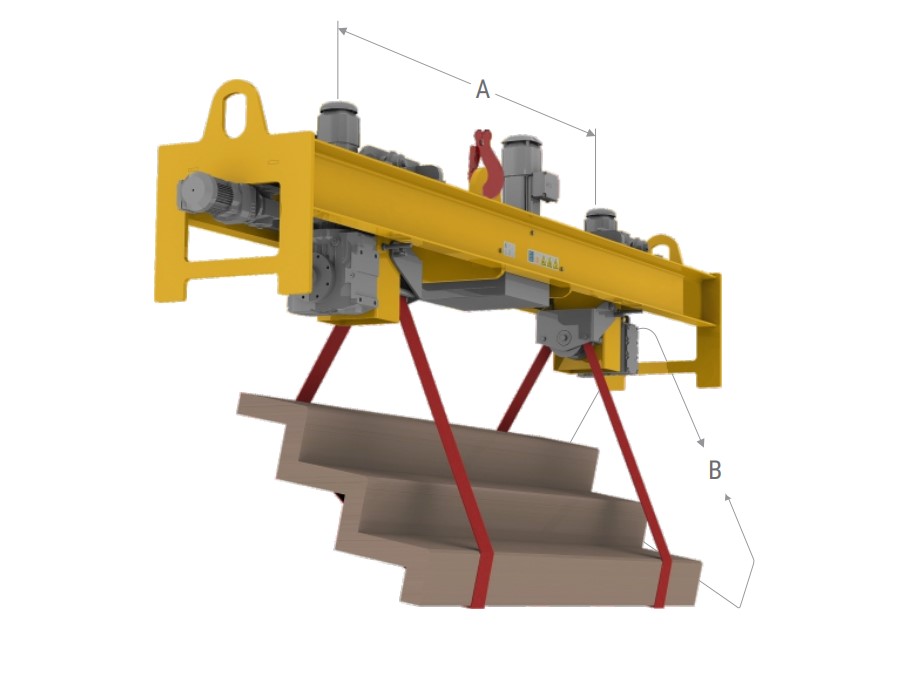

Polyurethane bending stiffeners play a great role in the installation and operation of submarine cables, umbilical cords and flexible pipes. Typical applications include free span flexible pipe/cable support to protect pipelines around other rigid structures (such as PLET, wellheads, cable joints and J/I pipe outlets). Unlike the bending stiffener, the bending limiter only provides protection after the wire reaches a certain bending radius. Bending ribs are usually made of polyurethane materials. In the submarine cable industry, the installation and operation of the polyurethane bending restrictor play a great protective role. Our company produces and processes customized marine cable bending stiffeners. If you are interested, please call us.

Bending restrictors are usually made of polyurethane.

The main advantage of curved restrictors over metal curved restrictors is that they do not require any local protection, and because of the low density of polyurethane materials, they usually add weight to the system.

The stiffener body is a flexible structure that is configured as an extended cone covered by a shorter cylindrical part. The main body has a cylindrical axial opening to accommodate the flexible tube. There is usually a nominal radial gap between the stiffener and the pipe-bonding stiffeners to the pipe is not common.

When the tube rotates relative to the end joint, the stiffener body will flex. This establishes the support tube structure and limits the restoring force of its curvature. The valve body effectively bears the load from the pipeline and provides another path for transmission to the end joint. This alternative route includes many of the following auxiliary components.

Bending restrictors are usually made of polyurethane.

The main advantage of curved restrictors over metal curved restrictors is that they do not require any local protection, and because of the low density of polyurethane materials, they usually add weight to the system.

The stiffener body is a flexible structure that is configured as an extended cone covered by a shorter cylindrical part. The main body has a cylindrical axial opening to accommodate the flexible tube. There is usually a nominal radial gap between the stiffener and the pipe-bonding stiffeners to the pipe is not common.

When the tube rotates relative to the end joint, the stiffener body will flex. This establishes the support tube structure and limits the restoring force of its curvature. The valve body effectively bears the load from the pipeline and provides another path for transmission to the end joint. This alternative route includes many of the following auxiliary components.