| Application of light crane in the factory

The KBK track is very common in factory lifting operations because it is suitable for all types of cranes for lifting operations, and it is safe and reliable.

CATEGORY:

CREATED:

Oct 25, 2019

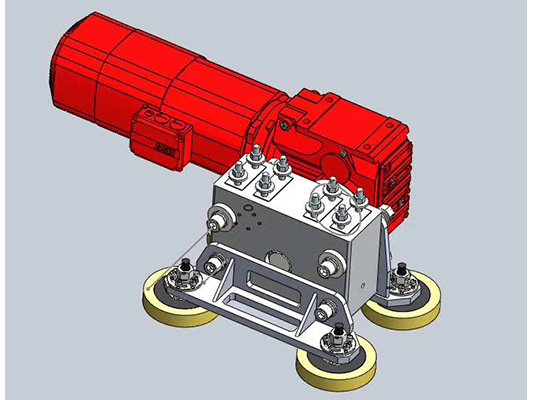

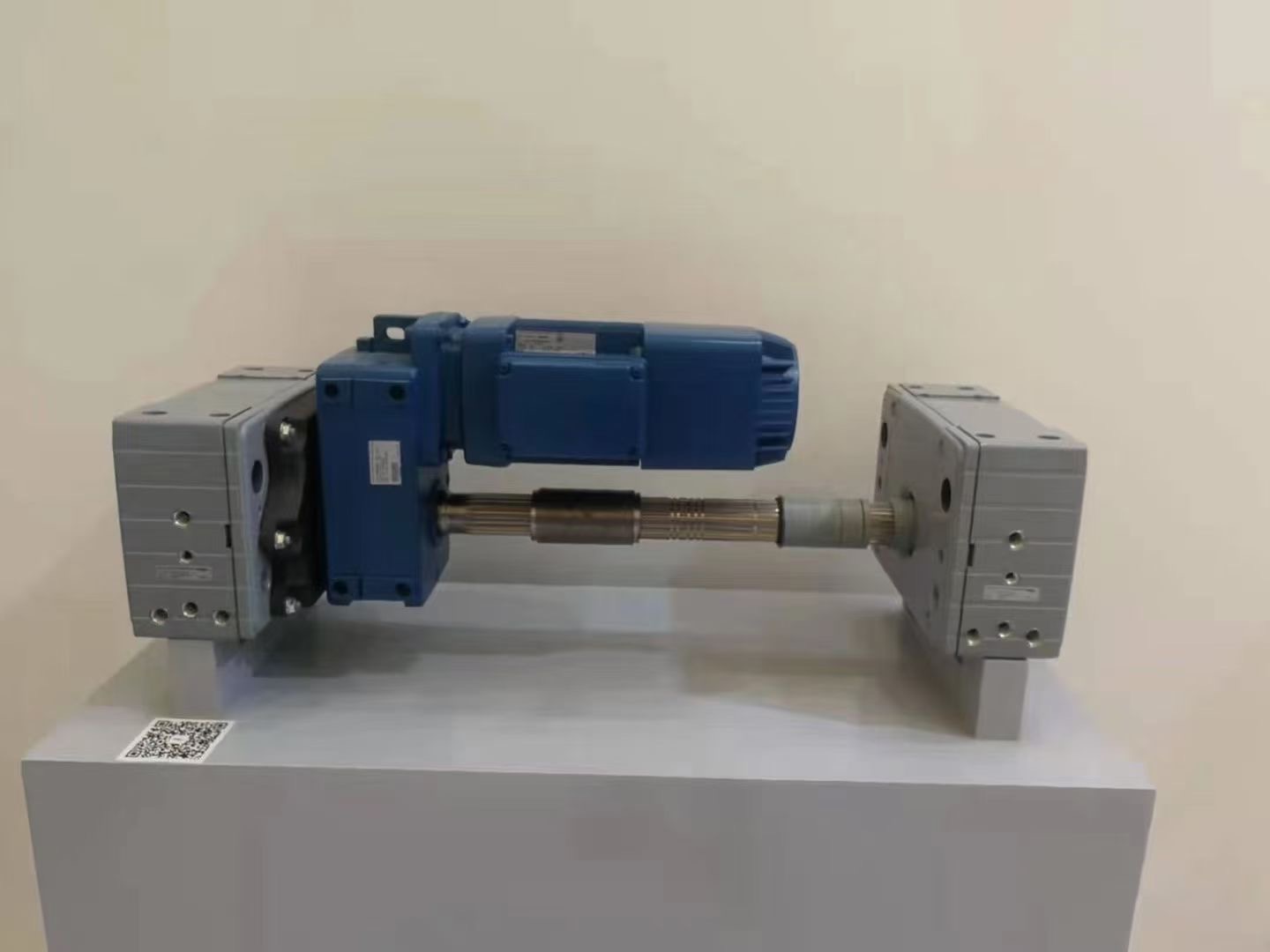

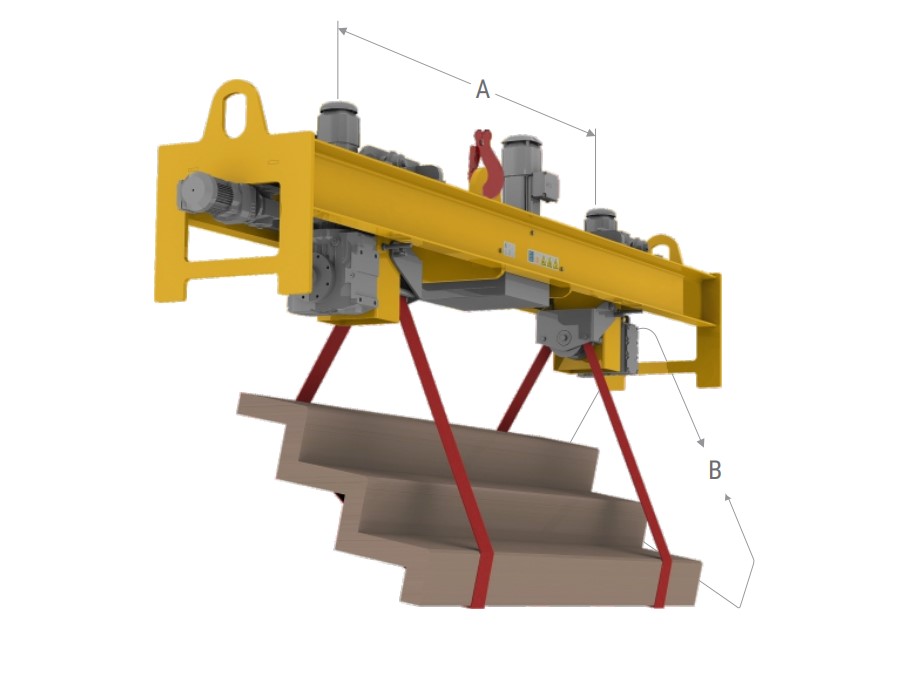

The KBK track is very common in factory lifting operations because it is suitable for all types of cranes for lifting operations, and it is safe and reliable. The extremely low failure rate is favored by many consumers. The kbk track is suspended by the crane. The combination of rails, ballasts, walking trolleys, electric hoists, mobile power supply devices (slip lines) and control devices can be used to directly transport materials in the air by simply hanging them on the roof or beam of the plant. It is applied to material conveying links or systems in all walks of life.

Each component of the KBK track is installed in a stand-alone module, ensuring efficient (referred to high performance) transport operations. The main advantages of the hanging crane include a lifting capacity of up to 2000 kg, light installation, safety and so on. Wire ropes are an indispensable part of cranes, including phosphate coated wire ropes, galvanized steel wire ropes and smooth steel wire ropes. Moreover, the main body of the track system module is three kinds of cold-rolled plates, which not only have high strength and rigidity, but also have very light weight, which makes the handling of the equipment very convenient and ensures the stability of the system to a certain extent (interpretation: stable stability; No change) Sex and safety!