| DRS wheel set that has high elasticity under high hardness and improves the wear resistance of the wheel surface

The features of DRS wheel block.

CATEGORY:

CREATED:

Apr 20, 2020

DRS wheel set :

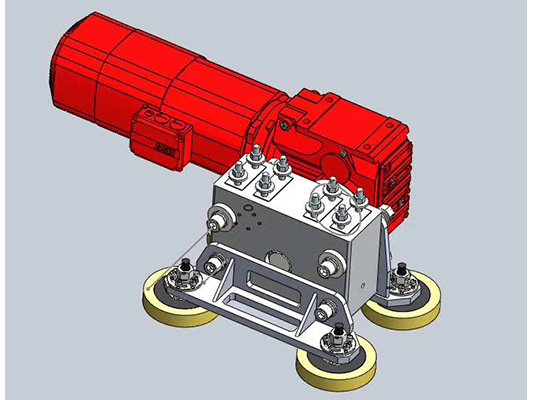

Wheel set refers to the mechanical equipment composed of wheels and shafts, bearings and bearing boxes. Wheels are devices used to support cranes and loads, and to make the crane reciprocate on the track. The main forms of wheel damage are wear, hardened lamination, and pitting. Compared with ordinary rubber rollers, the polyurethane walking wheel box has higher mechanical strength (2-3 times that of natural rubber), excellent abrasion resistance, (5-10 times that of natural rubber), and outstanding compression resistance. , A wide range of hardness, and still has high elasticity under high hardness.

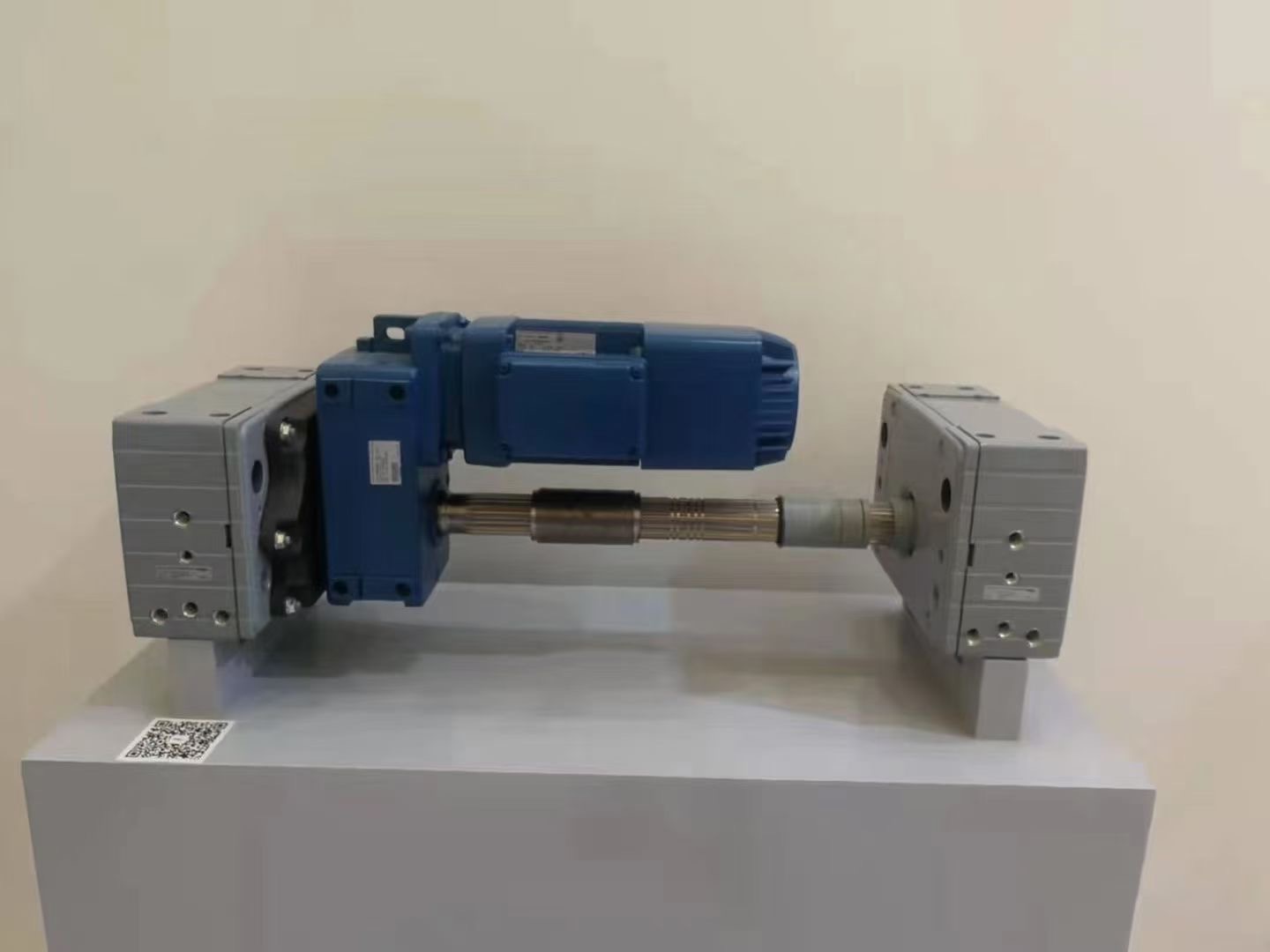

The material of the wheel is generally ZG430-640 cast steel. In order to improve the wear resistance and life of the wheel surface, the tread surface should be heat-treated. The surface hardness is HB300-350 and the quenching depth is not less than 20mm.

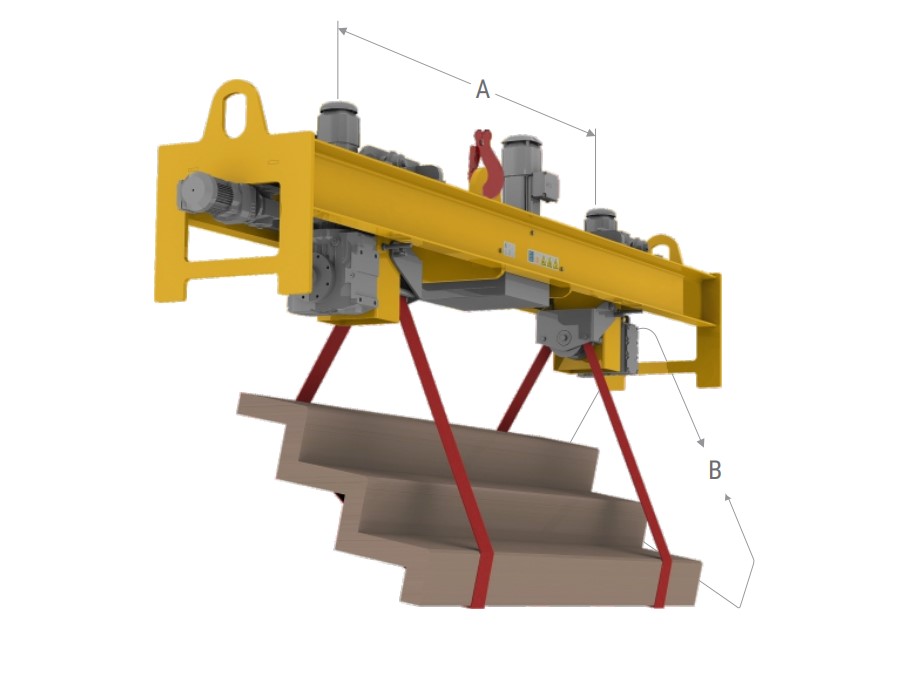

Crane wheel set: The horizontal deflection value of the wheel of the crane running mechanism is an important technical parameter of the crane. Excessive deviation of the deflection value will cause rails, increase running resistance, generate vibration and noise, increase track and wheel wear, and greatly reduce crane use. Life, so all kinds of crane manufacturing technical conditions must stipulate the allowable value for wheel horizontal deflection.

Can be customized accroding to your needs.

Wheel set refers to the mechanical equipment composed of wheels and shafts, bearings and bearing boxes. Wheels are devices used to support cranes and loads, and to make the crane reciprocate on the track. The main forms of wheel damage are wear, hardened lamination, and pitting. Compared with ordinary rubber rollers, the polyurethane walking wheel box has higher mechanical strength (2-3 times that of natural rubber), excellent abrasion resistance, (5-10 times that of natural rubber), and outstanding compression resistance. , A wide range of hardness, and still has high elasticity under high hardness.

The material of the wheel is generally ZG430-640 cast steel. In order to improve the wear resistance and life of the wheel surface, the tread surface should be heat-treated. The surface hardness is HB300-350 and the quenching depth is not less than 20mm.

Crane wheel set: The horizontal deflection value of the wheel of the crane running mechanism is an important technical parameter of the crane. Excessive deviation of the deflection value will cause rails, increase running resistance, generate vibration and noise, increase track and wheel wear, and greatly reduce crane use. Life, so all kinds of crane manufacturing technical conditions must stipulate the allowable value for wheel horizontal deflection.

Can be customized accroding to your needs.