| How to Maintain Crane Runways

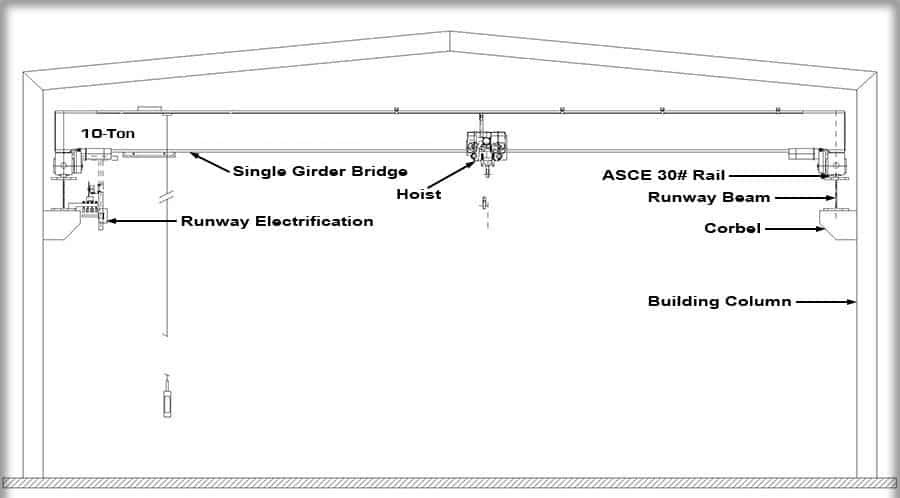

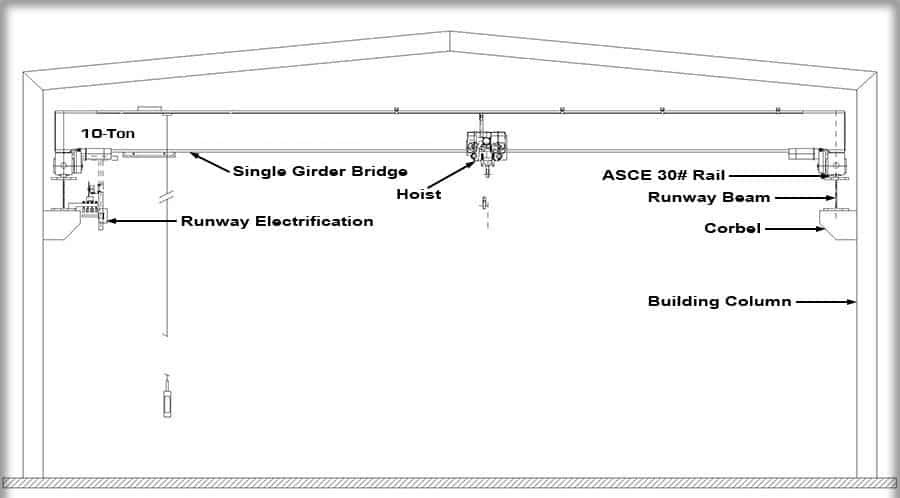

Crane Runway is a component of an overhead crane that provides support and rigidity to a bridge crane assembly. A perfectly aligned crane is an essential part in overhead crane. In the material handling working, incorrect rail alignment may result in a chain reaction, and it will result in wear and tear of rails and wheels.

It is important to address any observed problems promptly by engaging qualified technicians or crane maintenance professionals to conduct a thorough inspection and necessary repairs.

For example:

• Cracked wheel flanges

• A higher amount of power is needed to pass the crane system through the runway

• Abnormal deterioration of rails, wheels, and wheel bearings

• Wheels floating/climbing over the rail

How do you know that your crane runway has problems?

Irregular or Jerky Movement: If the crane experiences jerky or uneven movement along the runway, it could be a sign of misalignment, obstructions on the rails, or issues with the wheels and trolley. Smooth and consistent movement is essential for safe crane operation.

Excessive Vibration: Excessive vibrations transmitted through the crane or felt in the surrounding structures may indicate problems with the crane runway. It could be caused by loose or damaged components, misalignment, or worn-out rail surfaces.

Visual Inspection: Regular visual inspections can help identify visible signs of wear, damage, or misalignment on the crane runway. Look for cracks, deformations, loose bolts, worn-out rail surfaces, or any structural irregularities.

The specifications for aligning crane runways are highly complex and require careful application to avoid early failure of the runway. In fact, specialized steel must be fabricated for this purpose, as standard building steel is not designed to meet the necessary tight tolerances.

The specifications for aligning crane runways are highly complex and require careful application to avoid early failure of the runway. In fact, specialized steel must be fabricated for this purpose, as standard building steel is not designed to meet the necessary tight tolerances.

For example, the according to the National Standard of China, the recommendation of crane runway's tolerance is only 6 mm for a single bay runway, and no more than 1 cm. over the entire length of the runway.

Regular Inspection and Maintenance for Crane Runway

Regular inspections and maintenance can help identify and resolve issues early, ensuring the safe and efficient operation of the overhead crane runway.

Following are some measures to maintain a crane runway.

1. Regular Inspection: Conduct routine visual inspections of the crane runway to identify any signs of wear, damage, or misalignment. Look for issues such as cracks, loose bolts, worn-out rail surfaces, or any structural abnormalities.

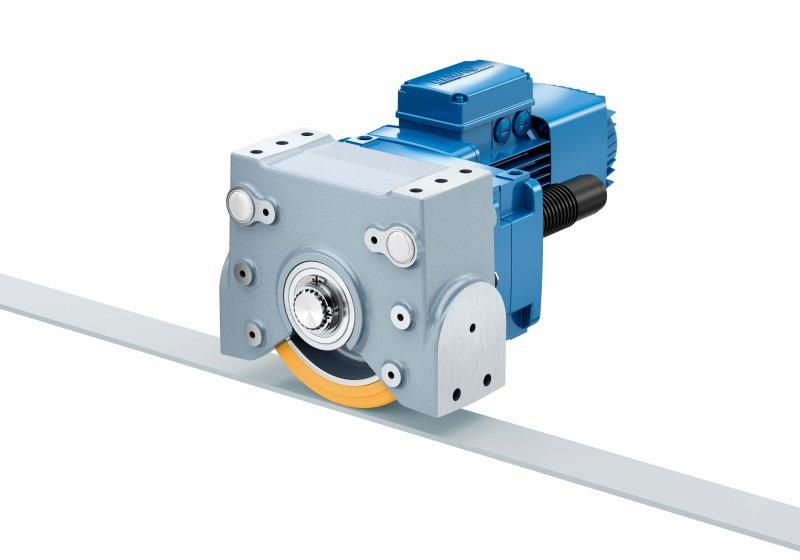

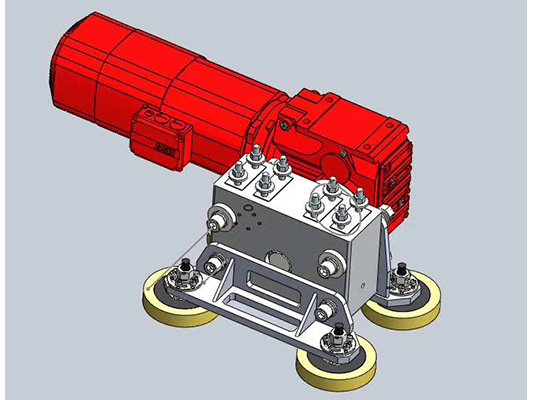

2. Lubrication: Apply lubrication to the crane runway rails and connections as recommended by the manufacturer. Proper lubrication reduces friction, ensures smooth movement, and prevents premature wear and tear.

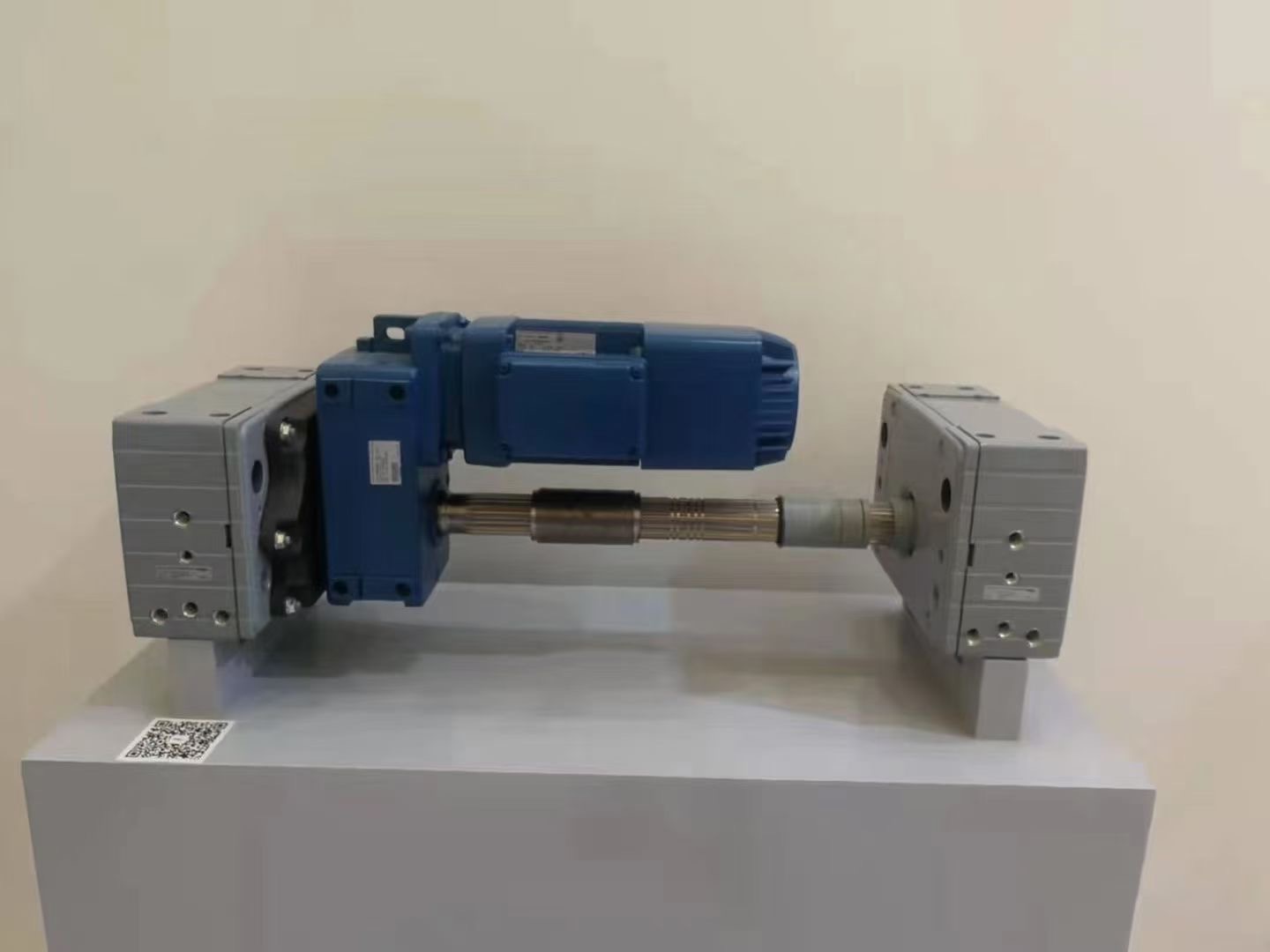

3. Alignment Check: Verify the alignment of the crane runway rails to ensure they are straight and parallel. Misaligned rails can cause excessive wear on the crane wheels, affect the crane's performance, and compromise safety.

4. Bolt Tightening: Check and tighten all bolts, fasteners, and connections to maintain the structural integrity of the crane runway. Loose or missing bolts can lead to instability and unsafe conditions.

5. Repair and Replacement: Promptly address any identified issues during inspections. Repair or replace damaged or worn components, such as rail sections, fasteners, or supporting structures, following manufacturer guidelines and industry standards.

6. Professional Maintenance: Engage qualified technicians or crane maintenance professionals to conduct periodic inspections and maintenance. They have the expertise to identify potential issues and perform specialized maintenance tasks for the crane runway.

7. Operator Training: Train crane operators on proper operation techniques, including avoiding sudden starts or stops, ensuring even load distribution, and minimizing impacts with the runway. Proper operation helps prevent unnecessary stress on the crane runway.

8. Documentation: Maintain a record of inspections, maintenance activities, repairs, and any modifications made to the crane runway. This documentation facilitates a comprehensive maintenance history and aids in tracking the condition of the runway over time.

9. Adhere to Manufacturer Guidelines: Follow the manufacturer's recommendations and guidelines for maintenance, inspections, and any specific requirements related to the overhead crane runway.

By following these maintenance practices, you can ensure the longevity, reliability, and safe operation of the crane runway while minimizing the risk of accidents or equipment failures.

About Us

As an ISO 9001:2015 certified organization, KUNFENG Cranes approach crane component with a well-defined quality management system (QMS). Our QMS involves adhering to ISO 9001 standard, meeting our own organization's requirements, applying your specifications and maintaining documentation throughout development.