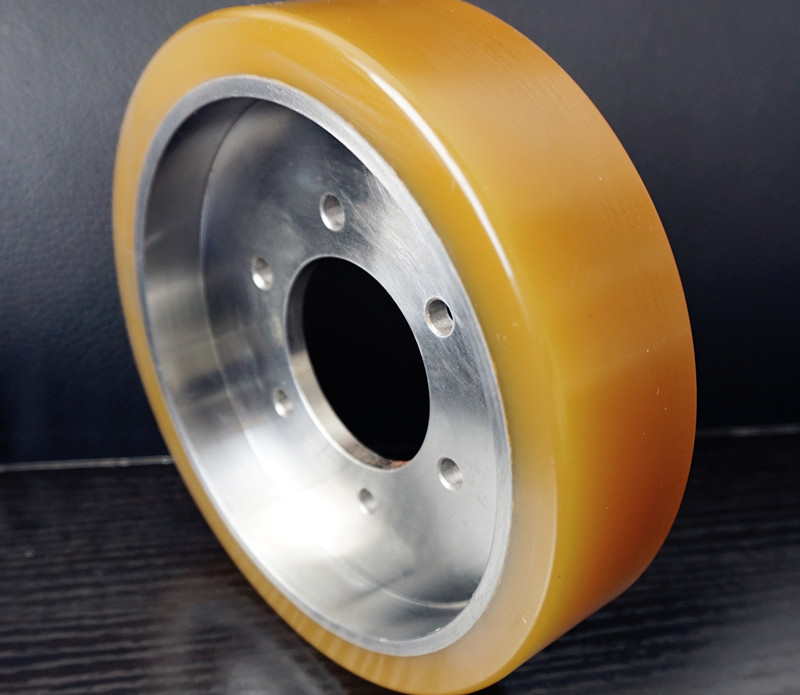

| Customized 3 Ton Polyurethane Casters

Polyurethane casters are wheels made of polyurethane material and are widely used in many industries such as logistics, manufacturing, and cleaning. The full name of polyurethane is polyurethane, among which TPU is called thermoplastic polyurethane, which is a polymer material with good recovery after external force is removed; while PU refers to polyurethane, which is a type of artificial leather and is also a polymer material. Polyurethane material exhibits excellent performance in caster manufacturing due to its unique physical and chemical properties.

Characteristics of polyurethane casters

● It has high wear resistance and can be used for a long time in a high friction environment without being easy to wear, which significantly extends the service life of the casters.

● Polyurethane materials have high resistance to most chemicals, remain stable in various corrosive environments, and are suitable for working in harsh environments.

● It has good elasticity and toughness, which can effectively reduce vibration and noise when the vehicle is driving, and improve the comfort and safety of transportation.

● It can withstand larger loads and ensure smooth driving of the vehicle even under heavy loads.

● The surface is smooth and does not easily absorb dust and dirt, making it easy to clean and maintain.

● Polyurethane material is easy to process into various shapes and sizes, and has good adhesive properties, making it easy to bond with a variety of metal and plastic materials, making the design of casters more flexible and customizable according to customer needs.

Meet customer customization needs

● Customer demand: A large logistics company needs to customize a batch of polyurethane casters with a load capacity of 3 tons for its heavy logistics vehicles. The casters are required to have high wear resistance, corrosion resistance and shock and noise reduction properties to adapt to complex transportation environments and condition.

● Material selection: High-strength polyurethane material is selected as the main material of the caster to ensure that the caster has excellent physical and chemical properties.

● Structural design: Special structural design is adopted to enhance the load-bearing capacity and stability of the casters to ensure that the vehicle can run smoothly even under heavy loads.

● Production process: After raw material preparation, mold manufacturing, production and other processes, a polyurethane caster that can carry 3 tons is finally produced.

● Testing and verification: After production is completed, the casters are subject to strict testing and verification, including load-bearing tests, wear-resistant tests, corrosion-resistant tests, etc., to ensure that the performance and quality of the casters meet customer needs.

KUNFENG CRANES, as a powerful and professional supplier of polyurethane products, has long provided high-quality polyurethane wheels to foreign customers. Welcome to contact us to customize products that meet your needs.