| Cleanroom Material Lifting Equipment for Medical Industry

| Want to know more about Cleanroom Material Lifting Equipment for Medical Industry?

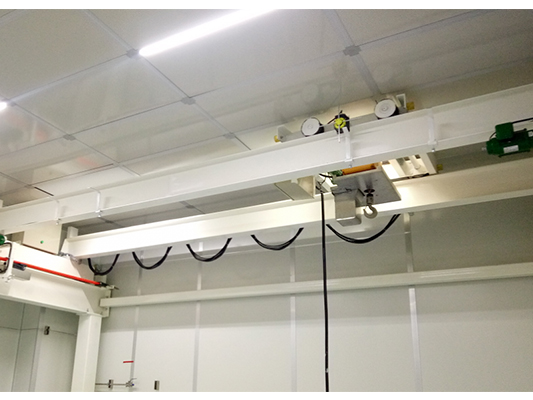

Clean room material lifting equipment refers to the crane used in clean rooms to lift and transport materials.

Clean room material lifting equipment refers to the crane used in clean rooms to lift and transport materials. The biggest feature of the clean room crane is that it can complete the transportation and lifting of materials while keeping the environment highly clean. This type of equipment is usually used in industries with extremely high cleanliness requirements, such as pharmaceuticals, semiconductor manufacturing, food production, etc.

Our design philosophy

Cleanroom material lifting equipment needs to use special materials such as dustproof, antistatic, and corrosion-resistant to ensure that the equipment itself does not become a source of pollution. At the same time, the structure of the equipment also needs to be carefully designed to reduce dust and particles generated during operation.

Professional manufacturing methods

Clean room material lifting equipment needs to undergo strict cleaning and inspection to ensure that the cleanliness of the equipment meets the requirements. In addition, the assembly and debugging of the equipment also need to be carried out inside the clean room to avoid the intrusion of external pollutants.

Maintain equipment with high cleanliness

Clean room material lifting equipment requires regular maintenance and upkeep to ensure that it is always in good working order. At the same time, operators also need to receive professional training and be familiar with the operating procedures and precautions of the equipment to avoid contamination problems caused by improper operation.

Types and applications of clean room material lifting equipment

According to different application scenarios and needs, clean room material lifting equipment can be divided into various types. Among them, the most common ones include clean room cranes and clean room electric hoists.

Clean room cranes usually adopt bridge or gantry structures and can be customized according to actual production needs. Dust-free cranes are dust-proof and anti-static and can complete large-tonnage and long-span lifting operations while keeping the environment highly clean. In industries such as pharmaceuticals and semiconductor manufacturing, dust-free cranes are widely used in material handling, assembly, testing and other aspects.

Clean room electric hoist is a small material lifting equipment, usually used for handling and lifting lightweight materials in clean rooms. It adopts electric drive mode and has the characteristics of small size, light weight and flexible operation. Clean room electric hoists have good dust-proof performance and can reduce environmental pollution to a certain extent. In industries such as electronics and precision instrument manufacturing, clean room electric hoists are widely used in operations such as transportation and assembly of parts.

Selection and use of clean room material lifting equipment

● Select appropriate equipment types, specifications and parameters based on actual production needs. For example, for large-tonnage and long-span lifting operations, you can choose a clean room crane; for the handling and lifting of lightweight materials, you can choose a clean room electric hoist, etc.

● Environmental factors such as temperature, humidity, and cleanliness in the clean room have a certain impact on the use and performance of the equipment. Therefore, you need to consider these factors when selecting equipment, and choose equipment with strong adaptability and good stability.

● Choosing products from well-known brands and high-quality services can ensure the quality of the equipment and the convenience of later use.

Application of clean room material lifting equipment in the medical industry

● Avoid material contamination during transmission and ensure the stability and reliability of product quality.

● Improve material transmission efficiency and reduce labor input to reduce production costs and improve corporate competitiveness.

● Realize automated and efficient transmission of materials, improve production efficiency, and shorten production cycle.

● Optimize the production environment and reduce the emission of noise, dust and other pollutants by reducing human participation and equipment failure rates.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China

sale@kfqizhongji.com

Contact

+86 (512) 55 000 225

Phone: +86 177 2978 0576

WhatsApp: +86 13390692151