| Semiconductor Clean Room Jib Crane | ISO Standard

| Want to know more about Semiconductor Clean Room Jib Crane | ISO Standard?

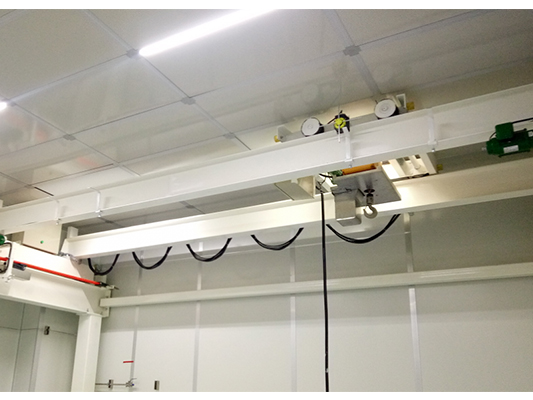

By using materials such as stainless steel, UHMW and synthetic lubricants, the cleanroom cranes are capable of operating in a class 10, 100, 1000, or 10000 cleanroom environments.

Compared with overhead crane, jib crane features a smaller and more compact design, which help to increase working productivity and improve workplace safety. There are three main types of jib crane, categorized based on their structural design and support attachment method:

• Free-standing jib crane

• Mast-type jib crane

• Wall-mounted jib crane.

A jib crane is a lifting device with an arm or boom protruding from the main body of the crane to provide additional reach. When integrated with manual hoist or electric hoist, jib crane can help your work in a wider application, for example, used in the cleanroom, in semiconductor industry, aerospace industry, electronic industry, etc. Our cleanroom jib crane are certified by semi certificate.

By using materials such as stainless steel, UHMW and synthetic lubricants, the cleanroom cranes are capable of operating in a class 100, 1000, or 10000 cleanroom environments, without producing flaking and corrosion.

The simple yet robust design makes them ideal for multiple applications such as in semiconductor industry and food industry. With maximum slew 360 degree, jib cranes are designed and optimised for use in clean room applications and operations.

In addition, the compact and portable structure allows jib crane installed on other equipment. When equipped with sensors, jib crane has a wide application in automation industry. Customized designs are available, for example, additional holes for sensors and cables, voltage, lifting speed, etc.

If you're interested in receiving more information or a quotation for a cleanroom crane, get in touch with our team on or email to sale@kfqizhongji.com.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China