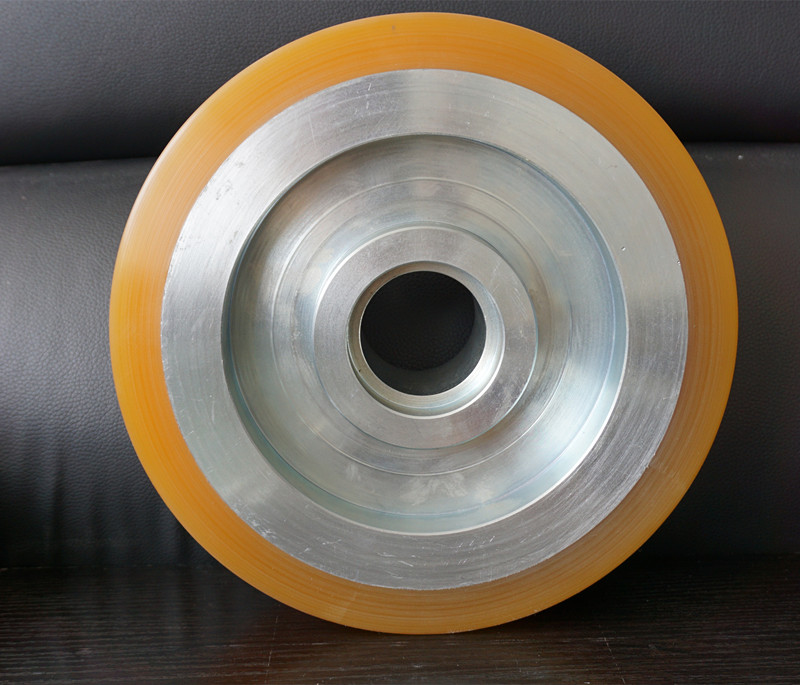

| Application of Polyurethane Coating Wheels on Monorail Crane

Polyurethane coating wheels are wheels that have been coated with polyurethane material. Due to its excellent properties such as high hardness, high strength, wear resistance, oil resistance, and corrosion resistance, polyurethane is widely used in various industrial fields, such as logistics, warehousing, transportation, food processing, woodworking machinery, mining machinery, and textile machinery.

Advantages of polyurethane materials

● Due to its excellent wear resistance, polyurethane material allows polyurethane coated wheels to maintain a low wear rate when in contact with the monorail for a long time and subjected to rolling and friction. This means the wheels last longer and need to be replaced less frequently, resulting in lower maintenance costs.

● The high elastic modulus and good resilience of polyurethane materials enable polyurethane coated wheels to better absorb energy when they are impacted or vibrated, reducing impact damage to the monorail crane system and tracks. This is important to maintain system stability and extend the service life of the track.

● Polyurethane coating wheels can be customized according to specific needs during the design and manufacturing process to meet different working environments and load requirements.

In the monorail crane system, the application of polyurethane coating wheels is mainly reflected in its role as friction drive wheels. Vulkollan polyurethane is a premium material in this field, known for its excellent wear resistance, high tensile strength and tear resistance. These properties allow the Vulkollan polyurethane coating wheels to withstand friction with the track surface for extended periods of time without significant wear, thus significantly extending the service life of the drive wheels. At the same time, the material can maintain good shape stability under long-term pressure, which is crucial to maintaining the accuracy and stability of the monorail crane system.

Application case of polyurethane coating wheels on monorail crane

● In mining environments, monorail crane systems are often used for lifting materials, towing vehicles and other operations. Due to the complex mining environment, the equipment has higher requirements for wear resistance, load-bearing capacity and impact resistance. Polyurethane coating wheels are widely used in mining monorail crane systems due to their high wear resistance, excellent load-bearing capacity and tear resistance. These coating wheels can withstand heavy loads and complex working conditions in mines, ensuring the stability and safety of the monorail crane system. At the same time, polyurethane materials can withstand harsh environmental factors in mines, such as moisture, dust, etc., extending the service life of the equipment.

● In tunnel construction, the monorail crane system is also an indispensable piece of equipment. The space inside the tunnel is limited, and the environment is humid and dark, which requires higher performance of the equipment. Polyurethane coating wheels play an important role in the tunnel monorail crane system due to their low noise and good shock absorption properties. They can reduce the noise and vibration generated by equipment during operation, providing construction workers with a quieter and more comfortable working environment. At the same time, the high wear resistance of polyurethane coating wheels also ensures long-term stable operation of the equipment in harsh tunnel environments.

● Polyurethane coating wheels can be customized according to specific needs to meet the use requirements in different scenarios. For example, in scenarios that require high load-bearing capacity, you can choose a polyurethane formula with higher hardness and strength; in scenarios that require low noise and good shock absorption performance, you can choose a formula with better elasticity. This customized service makes the application of polyurethane coating wheels in monorail crane systems more flexible and extensive.