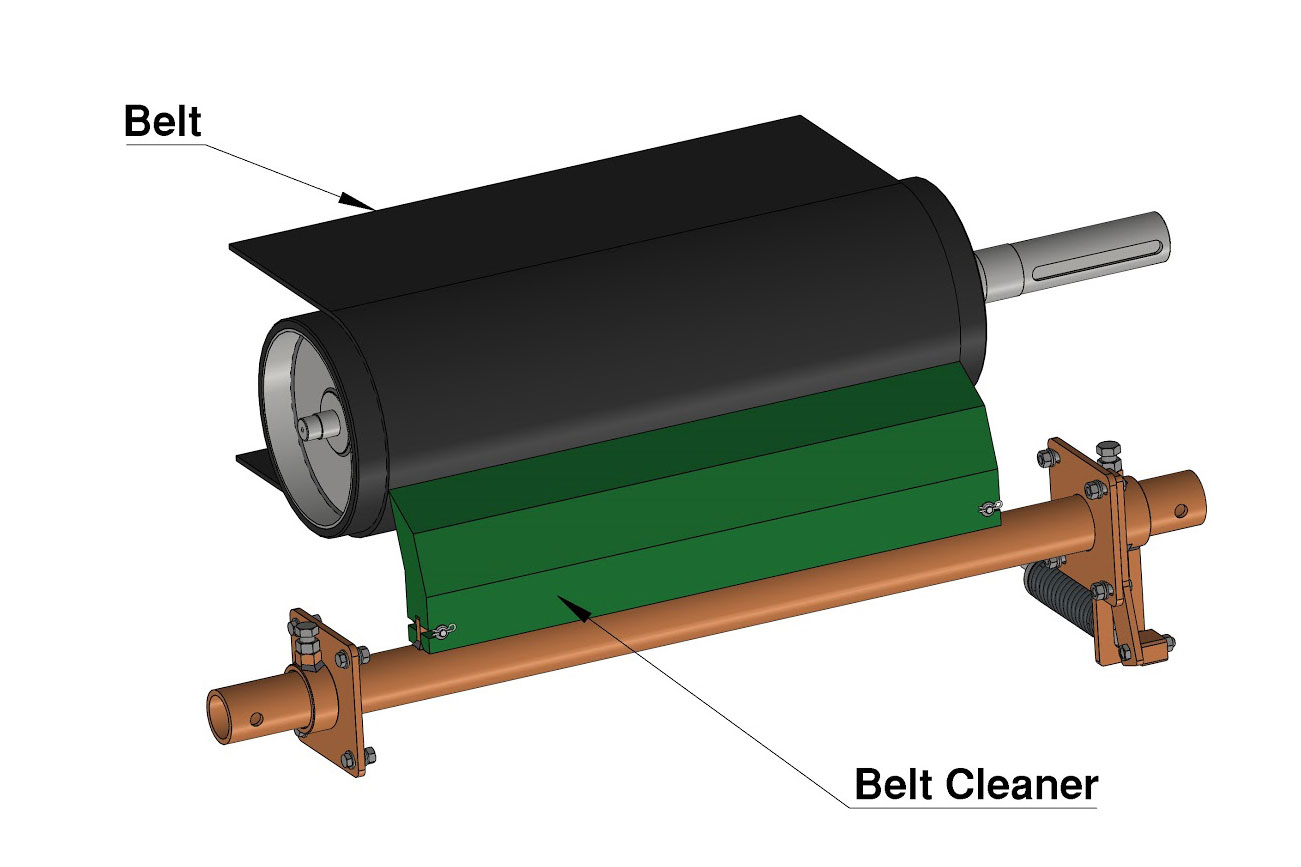

| Wear Resistant Polyurethane Belt Cleaners for Mining

| Want to know more about Wear Resistant Polyurethane Belt Cleaners for Mining?

Wear-resistant polyurethane belt cleaners offer exceptional durability, low maintenance, and efficient material removal, ensuring the longevity and reliability of conveyor systems in harsh mining environments.

In the mining industry, conveyor belts are a critical component of the material transportation process. Over time, the accumulation of material on the belt can lead to inefficiencies and potential system failures. The wear-resistant polyurethane belt cleaner plays a vital role in maintaining the performance and longevity of these conveyor systems.

Key Features of Polyurethane Belt Scrapers

High Abrasion Resistance: Polyurethane is renowned for its exceptional resistance to wear and tear, making it an ideal material for belt cleaners used in the harsh conditions of mining.

Long Service Life: Due to the durability of polyurethane, the belt cleaners can last significantly longer than those made from other materials, reducing the frequency of replacements and maintenance.

Low Maintenance: The robust nature of polyurethane means that these belt cleaners require minimal upkeep, which translates to cost savings and less downtime.

Versatility: Polyurethane belt cleaners are suitable for various types of conveyor belts and can handle a wide range of materials, from coal and ore to heavy clays and abrasive materials.

Customizable Design: These belt cleaners can be customized to fit the specific dimensions and requirements of different mining operations, ensuring a perfect fit and optimal performance.

Benefits in Mining Applications

Efficient Cleaning: Polyurethane belt cleaners effectively remove residual material from the conveyor belt, ensuring efficient and consistent operation.

Reduced Material Loss: By preventing carryback and spillage, these cleaners help to minimize material loss and reduce the environmental impact of mining activities.

Improved Safety: The consistent cleaning action of the polyurethane cleaners reduces the risk of belt slippage and damage, contributing to a safer working environment.

Cost-Effectiveness: Although the initial investment in polyurethane belt cleaners may be higher than for conventional materials, the long-term savings in maintenance and replacement costs make them a cost-effective choice.

Environmental Considerations: Polyurethane is a more environmentally friendly material compared to some traditional materials used in belt cleaners, aligning with the mining industry's move towards greener practices.

Wear-resistant polyurethane belt cleaners offer a reliable and efficient solution for maintaining conveyor belt systems in the mining industry. Their durability, low maintenance requirements, and customizable design make them an excellent investment for mining operations looking to enhance productivity and safety while reducing environmental impact. As the mining sector continues to embrace technological advancements, the adoption of polyurethane belt cleaners is set to grow, offering a sustainable approach to conveyor maintenance.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China