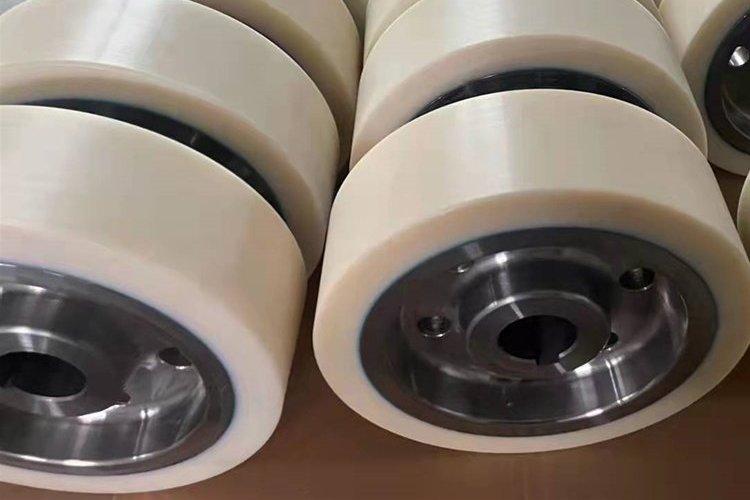

| Polyurethane Coating Wheels in Semiconductor Workshop

Polyurethane (PU) coated wheels are highly valued in semiconductor workshops for their unique properties that make them ideal for the precise and clean environment required in these settings. Here's an overview of the benefits and applications of polyurethane coated wheels in semiconductor workshops:

Benefits of Polyurethane Coated Wheels

1. High Abrasion Resistance: Polyurethane is known for its exceptional abrasion resistance, which is crucial in environments where wheels come into frequent contact with surfaces, reducing the need for frequent replacements .

2. Impact Absorption: The material's elasticity allows it to absorb shocks and vibrations, protecting both the wheel and the transported items from damage.

3. Low Rolling Resistance: Polyurethane wheels offer low rolling resistance, which contributes to energy efficiency and easier movement of equipment.

4. Chemical Resistance: They are resistant to a wide range of chemicals, making them suitable for use in environments where chemical exposure is a concern.

5. Noise Reduction: The use of polyurethane material results in quieter operation, which is beneficial in sensitive semiconductor workshops where noise control is important.

6. Non-Marking and Non-Staining: Polyurethane wheels are non-marking and non-staining, ensuring that they do not leave marks or residues on the cleanroom floors .

Applications in Semiconductor Workshops

1. Material Handling Equipment: Used in equipment like stackers and conveyor systems for moving wafers, components, and other materials within the semiconductor manufacturing process.

2. Cleanroom Transport: Ideal for cleanroom environments due to their non-abrasive and non-conductive properties, which prevent contamination and ensure a clean, controlled environment.

3. Precision Machinery: Polyurethane wheels are used in precision machinery that requires smooth and controlled movement, such as in photolithography and etching processes.

4. Maintenance and Repair: The wheels are also used in maintenance and repair tasks within the semiconductor workshop, where clean and reliable equipment movement is essential.

Customization Options

1. Hardness Range: Polyurethane wheels can be customized with different hardness levels, ranging from Shore 5A to 98A to 80D, to suit specific application needs .

2. Color Options: Over 30 stocked color options and customized colors are available, allowing for easy identification and compliance with specific workshop requirements.

3. Material Compounding: Companies like KUNFENG Cranes specialize in formulating polyurethane compounds to serve the purpose of the application, offering high resilience and durability .

Polyurethane coated wheels provide a reliable and efficient solution for material handling and transportation in semiconductor workshops. Their combination of durability, chemical resistance, and low maintenance make them a preferred choice in an industry where cleanliness and precision are paramount. By selecting polyurethane wheels, semiconductor manufacturers can ensure the smooth operation of their equipment and maintain the high standards required for their products.