| Crane Wheels with Pneumatic Friction System

| Want to know more about Crane Wheels with Pneumatic Friction System?

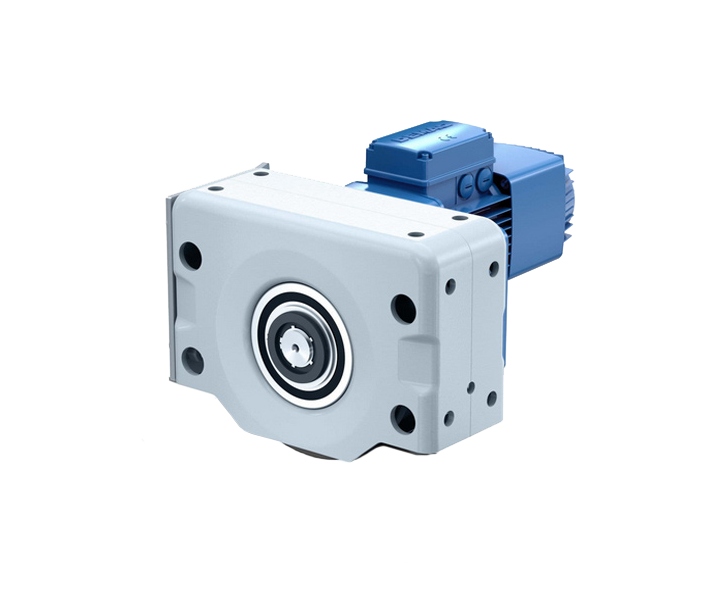

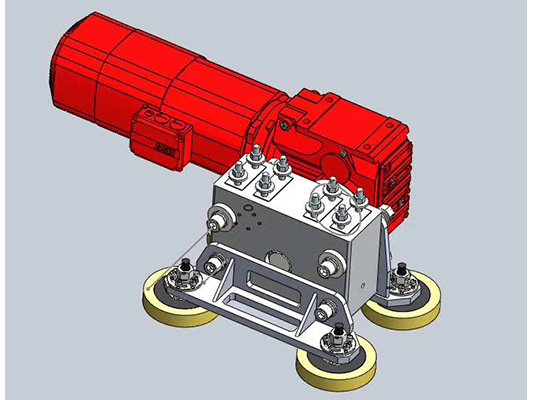

Crane wheels with pneumatic friction system is a special wheel device that realizes braking control through pneumatic drive. Its core consists of a pneumatic brake module, a high-wear-resistant fricti

Crane wheels with pneumatic friction system is a special wheel device that realizes braking control through pneumatic drive. Its core consists of a pneumatic brake module, a high-wear-resistant friction plate and a pressure regulating mechanism. When working, the system uses compressed air to accurately adjust the contact pressure between the friction plate and the rail or wheel hub, thereby dynamically controlling the braking torque, which can not only achieve smooth start and stop and load anti-slip, but also respond quickly to complete safe braking in emergency situations. The system has a wear-resistant, high-temperature-resistant and dust-proof design, and is particularly suitable for industrial scenarios with high loads, frequent starts and stops or harsh environments. It can significantly improve the stability and safety of crane operation while reducing long-term maintenance costs.

The models of crane wheels with pneumatic friction system are usually customized or classified by manufacturers according to specific application requirements. Common distinguishing dimensions include load capacity (such as light load, medium load, heavy load), wheel diameter (such as Φ200mm to Φ500mm), brake module design (integrated or split) and applicable environment (such as explosion-proof, high-temperature resistant, corrosion-resistant, etc.). For example:

● Light series (such as QZ-L series): suitable for low load, indoor environment, and small adjustable range of braking torque.

● Heavy series (such as QZ-H series): for high load scenes such as ports and metallurgy, equipped with high temperature friction plates and enhanced brake modules.

● Explosion-proof type (such as QZ-Ex series): meets explosion-proof certification and is suitable for hazardous environments such as chemical industry and mining.

Main design features of Crane wheels with pneumatic friction system

● The use of high-strength materials and optimized structural design allows the wheels to withstand high loads and is suitable for heavy cranes and high-frequency operation environments.

● The wheel has a built-in pneumatic friction system that can automatically adjust the friction according to load and speed changes, provide stable braking force, and reduce heat and wear generated by friction.

● The wheel material is made of wear-resistant and corrosion-resistant alloys or special coatings, which can cope with high-frequency use and harsh environmental conditions.

● It has a high degree of modularity, which is convenient for quick replacement and maintenance, reducing equipment downtime.

● Equipped with precise pressure control devices to ensure accurate friction adjustment, it can provide smooth braking effect under different working conditions.

We are a professional supplier of crane wheels. If you have any purchasing needs, please contact us for free customized design and preferential quotations!

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China