| What are the Causes of Crane Wire Rope Fatigue?

What are the causes of crane wire rope fatigue?

1. Fatigue

1. Fatigue

The wire rope of the crane undergoes bending fatigue and fatigue induced by stretching, twisting, and vibration during operation.

2. Bending fatigue

When a crane's wire rope is repeatedly bent by the pulley or reel, it undergoes multiple flexes which can cause fatigue in the steel wire. This leads to a decrease in toughness and eventually results in a broken wire. The breakage usually occurs on the outer wire of the strand where the curvature is most severe. When fatigue broken wire is visible, it indicates that the wire rope is approaching the end of its useful life.

Studies indicate that the fatigue life of a crane's wire rope is significantly influenced by its D/d ratio (which is the ratio of the drum's diameter to the wire rope's diameter), the safety factor, and the wire rope's structure.

3. Fatigue caused by stretching, twisting and vibration

At the beginning and end of the start and brake of the wire rope crane hoist, the tensile stress of the bundled wire rope before and after the load can cause metal fatigue. In addition, the fact that the wire rope is often subjected to distortion and vibration is also a cause of fatigue.

The principle of fatigue damage is that under the action of variable stress, the surface of the thin steel wire first forms initial cracks due to various slips, and then the crack tip repeatedly plastically deforms under the action of shear stress, so that the crack propagates until fracture. The broken wires caused by fatigue are generally flush, and most of them appear on the surface steel wire, and they are very regular.

Do you know how to maintenance wire rope hoist? And what frequency is suggested? Learn more at the maintenance of wire rope hoist.

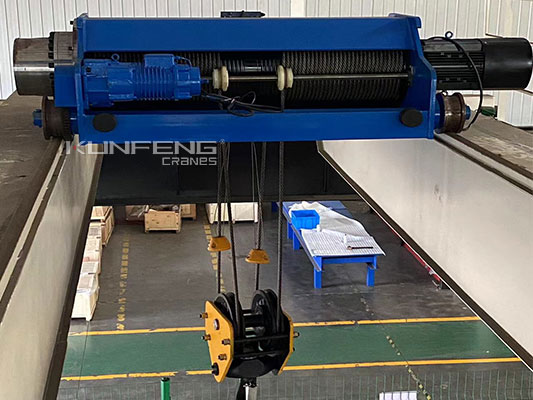

Interest in Wire Rope Hoist? Contact KUNFENG Cranes to get a free quotation today!