| 10 ton Workstation Overhead Crane - Double girder, Wire rope hoist

| Want to know more about 10 ton Workstation Overhead Crane - Double girder, Wire rope hoist?

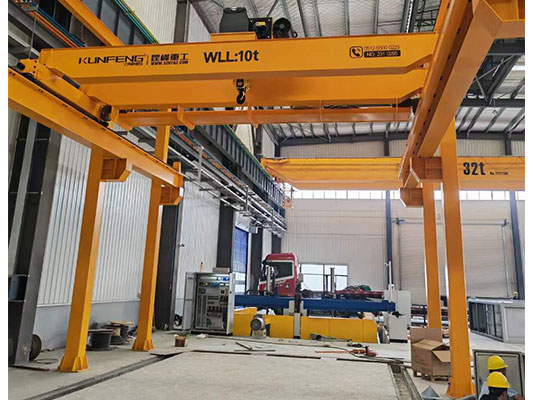

Different with light workstation crane, this 10 ton capacity workstation overhead crane is ideal for heavy lifting tasks in industrial environments. This robust top running crane features a double girder bridge structure and wire rope hoist.

Workstation crane are not only composed of aluminum alloy or stainless steel, there are steel workstation crane as well. Different with light workstation crane, this 10 ton capacity workstation overhead crane is ideal for heavy lifting tasks in industrial environments. This robust top running crane features a double girder bridge structure and wire rope hoist.

• Double Girder Bridge

The crane bridge is constructed from two welded I-beams, providing greater strength and load stability compared to single girder designs. The double girder style allows lifting larger payloads at greater spans up to 50 feet.

• Power and Control

Controlled by a convenient wireless pendant, the hoist motor provides smooth, responsive lifting of loads. An upgraded 3-ton lifting capacity allows easy handling of denser materials. Optional festooning keeps hoist cables neatly organized.

Mounted on wheels that glide easily along the bridge, the hoist trolley allows lateral movement across the full work zone. Standard mechanical stops locate the trolley at predefined positions with repeatable accuracy.

• End Carriages

Rugged end carriages with multiple wheels support the bridge beams for maximum durability. DRSA wheel block system is a good option for crane travelling. When coated with PU, these modular crane has a more stable moving and make wheel blocks more corrosive. Sealed bearings require no maintenance and minimize friction for trouble-free operation.

• Power and Drives

Driven by high-efficiency three phase AC gearmotors, the crane components move precisely through programmable PLC controls. Emergency stops and upper limit switches ensure safe operation.

• Structural Components

Welded box girder main and leg columns provide an exceptionally robust lift-duty structure. Increased height clears production equipment. Ball bearing technology at all rotation points enhances structural integrity.

• Overhead Protection

Protective barriers, fluorescent lighting, lifting eyes, and safety signs comply with industrial lifting safety standards to keep work areas free of obstruction or environmental issues.

• Low Maintenance Design

With minimal wearing parts, top running overhead crane delivers years of reliable use with only routine inspections required. Its advanced design means any needed repairs can be easily completed with standard hand tools.

If you are interested in overhead workstation crane, please contact us to discuss more on your projects. Top running overhead crane can improve safety, workflow and productivity within your industrial facility. Durable construction and lifting capacity handling a wide range of load weights make it ideal for many material handling applications.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China