| DRSA 250 Drive Wheel Block Supplier

| Want to know more about DRSA 250 Drive Wheel Block Supplier?

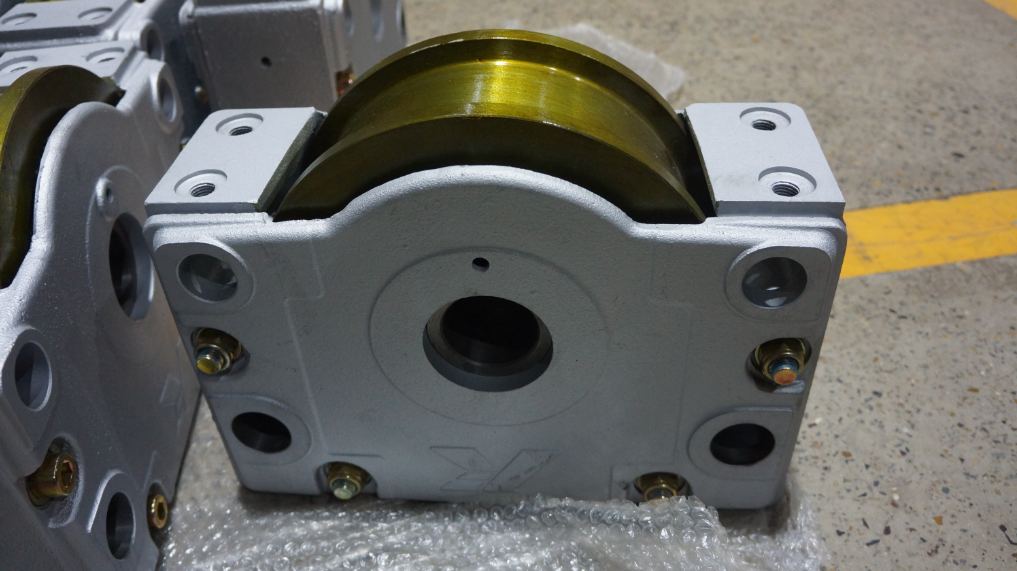

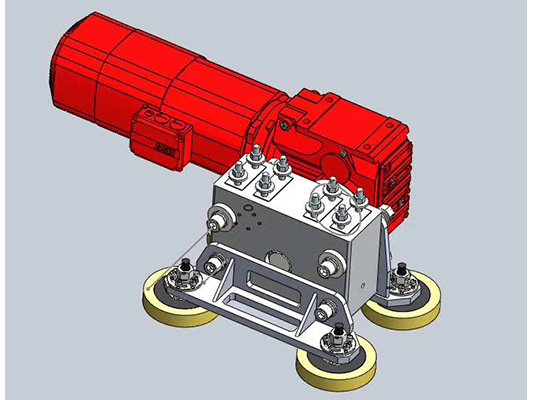

The DRSA 250 drive wheel block is a model in the DRSA series of high-performance drive wheel assemblies for industrial cranes and automation equipment, designed to provide efficient and stable load transfer and motion control.

The DRSA wheel block system is a high-performance drive wheel assembly for industrial cranes and automation equipment designed to provide efficient and stable load transfer and motion control. This system is mainly used for cranes and automation equipment suspended on rails to ensure that they can move smoothly along the rails and complete load transfer efficiently. DRSA 250 drive wheel block is a model in the DRSA series. Its advanced production technology and superior performance characteristics enable it to provide stable and reliable support in various harsh application conditions.

DRSA 250 wheel block specifications (Reference)

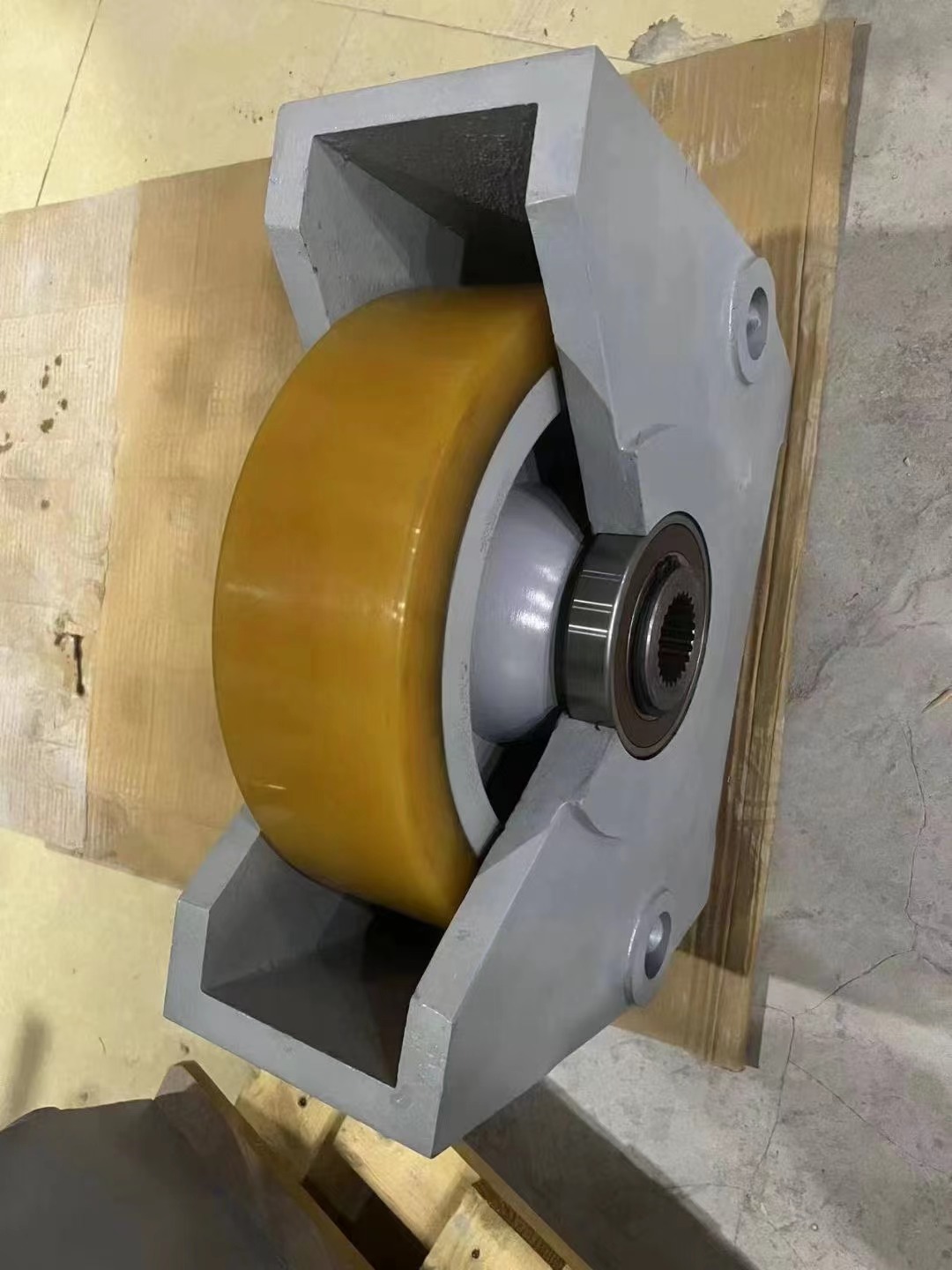

● Load capacity: 5 tons

● Wheel diameter: 250mm

● Wheel width: 100mm

● Drive power: 1.5 kW

● Reduction ratio: 10:1

● Installation method: The standard installation hole distance is 150mm

● Material: high-strength alloy steel, anti-corrosion coating

● Operating temperature range: -20℃ to +50℃

● Dimensions: 350mm x 250mm x 250mm

● Weight: 25kg

Production process

● DRSA 250 drive wheel blocks are manufactured through high-precision machining processes, including CNC lathe and milling, to ensure accuracy and consistency in every part.

● High-strength steel and wear-resistant alloy materials are selected, heat treated and surface hardened to improve durability and load-bearing capacity.

● During the production process, components undergo rigorous assembly and testing to ensure that each wheel block's performance in actual operation meets standards.

Main features

● Able to withstand heavy loads and high-intensity operating conditions, it is suitable for use in demanding industrial environments.

● Equipped with a high-precision driving wheel system to ensure that the power of the motor can be effectively transmitted, reducing energy loss and improving the overall efficiency of the system.

● The wheel blocks are made of high-strength, wear-resistant materials to extend service life and reduce maintenance frequency.

● Equipped with shock absorption function and optimized wheel set design, it reduces vibration and noise during operation and provides a smooth sports experience.

● Treated with anti-corrosion coatings or materials for use in a variety of environments, including wet and corrosive environments.

Application conditions

● Used in various industrial cranes, including overhead cranes, gantry cranes, etc., to help equipment move smoothly on the track and carry heavy objects.

● Used in automated production lines and warehousing systems to transport and move materials to improve production efficiency and automation levels.

● In logistics and warehousing centers, the DRSA 250 wheel block system helps handle and transfer heavy goods to support high-load operation requirements.

KUNFENG CRANES' DRSA wheel block system provides customers with stable and reliable load handling solutions with its excellent load capacity, high-precision drive system and durable materials. Contact us for more product information and non-standard custom designs.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China