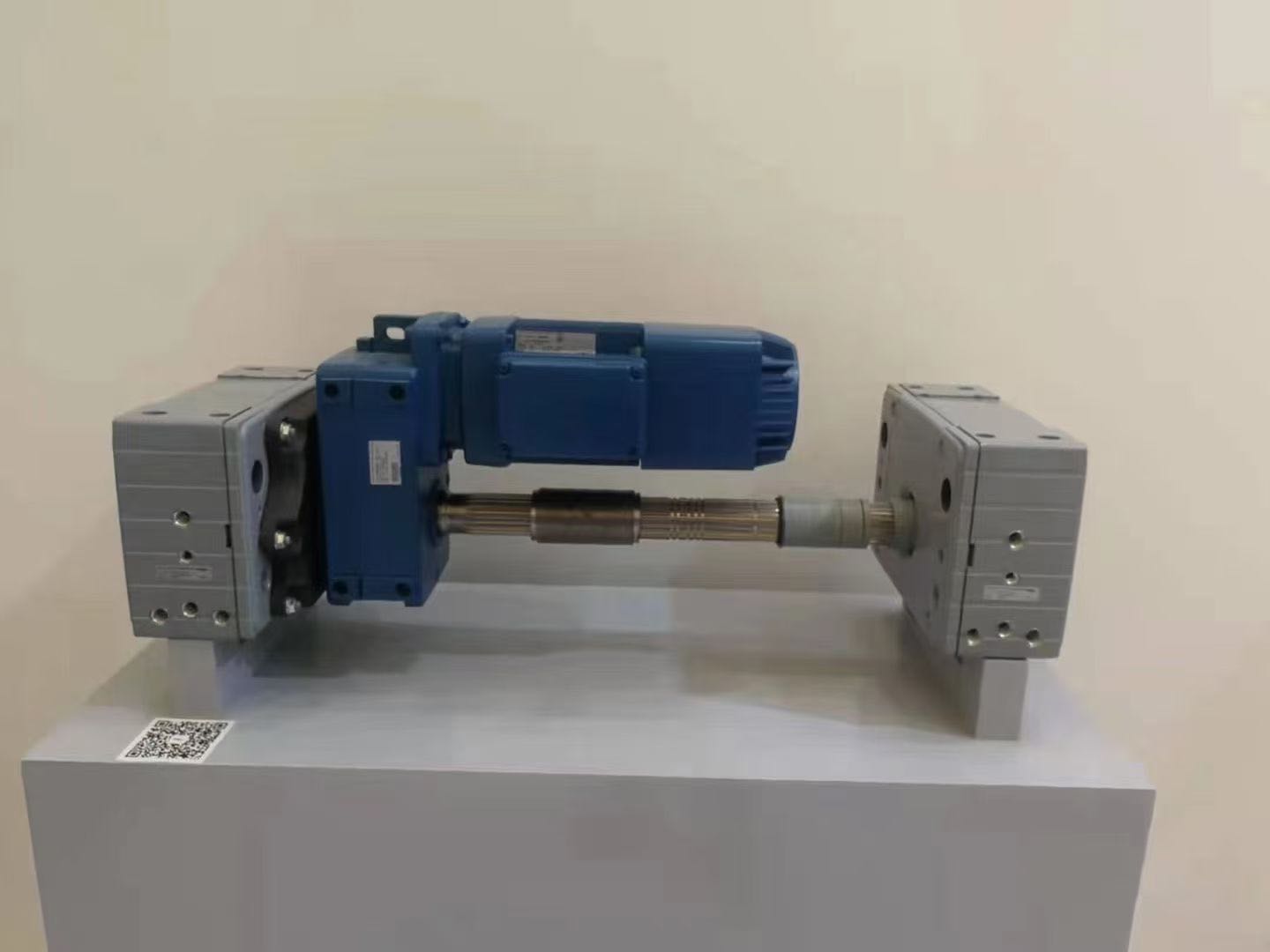

| Warehouse Stacker Traveling Wheels

| Want to know more about Warehouse Stacker Traveling Wheels?

Warehouse stacker traveling wheels are the main components of the stacker traveling between warehouse shelves. They are usually composed of hubs, spokes, rims and bearings.

Warehouse stacker traveling wheels are the main components of the stacker traveling between warehouse shelves. They are usually composed of hubs, spokes, rims and bearings. The quality of the traveling wheels is directly related to the operating efficiency, stability and safety of the stacker. Therefore, when selecting and using warehouse stacker traveling wheels, factors such as wear resistance and load-bearing capacity need to be fully considered.

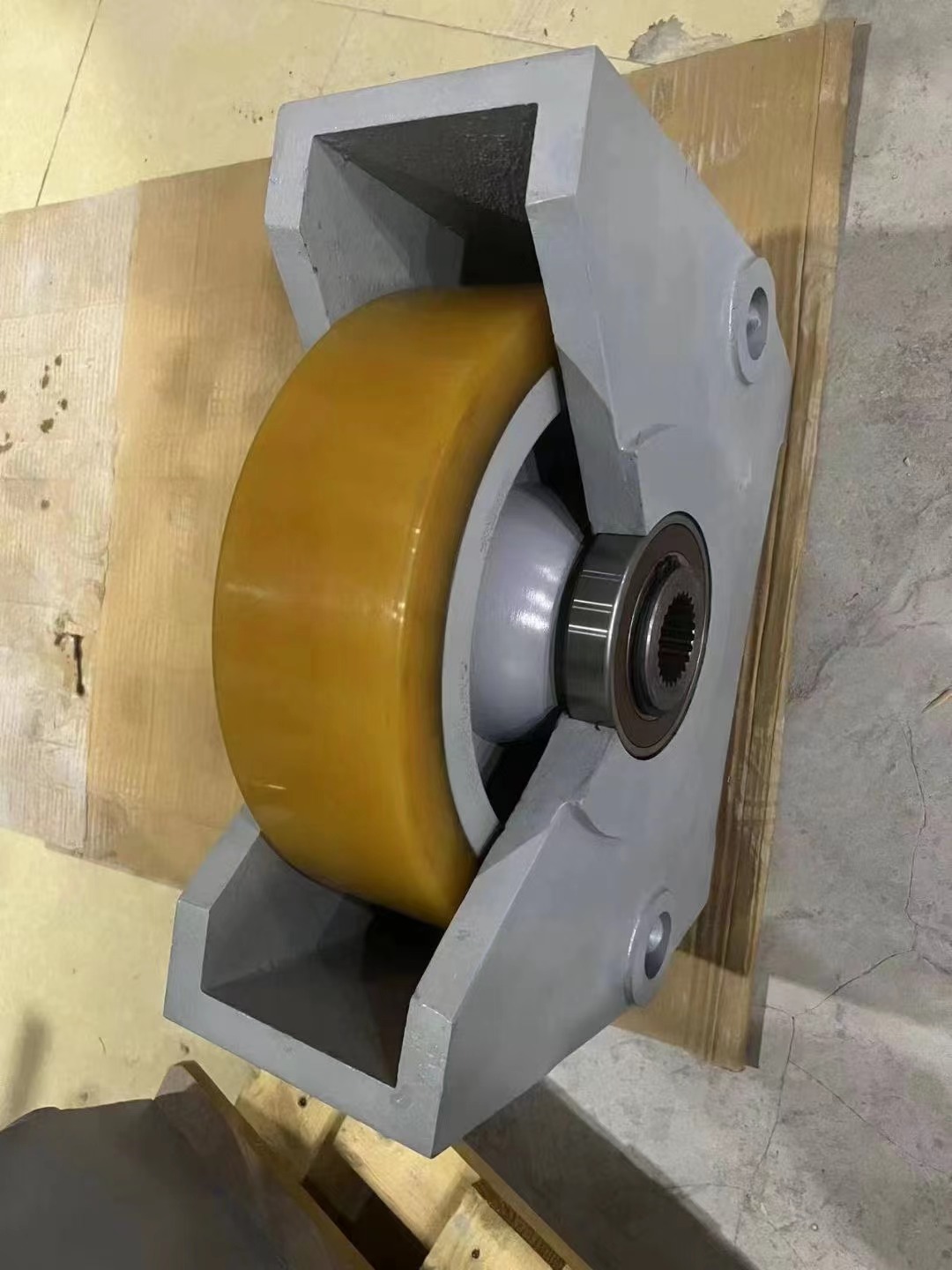

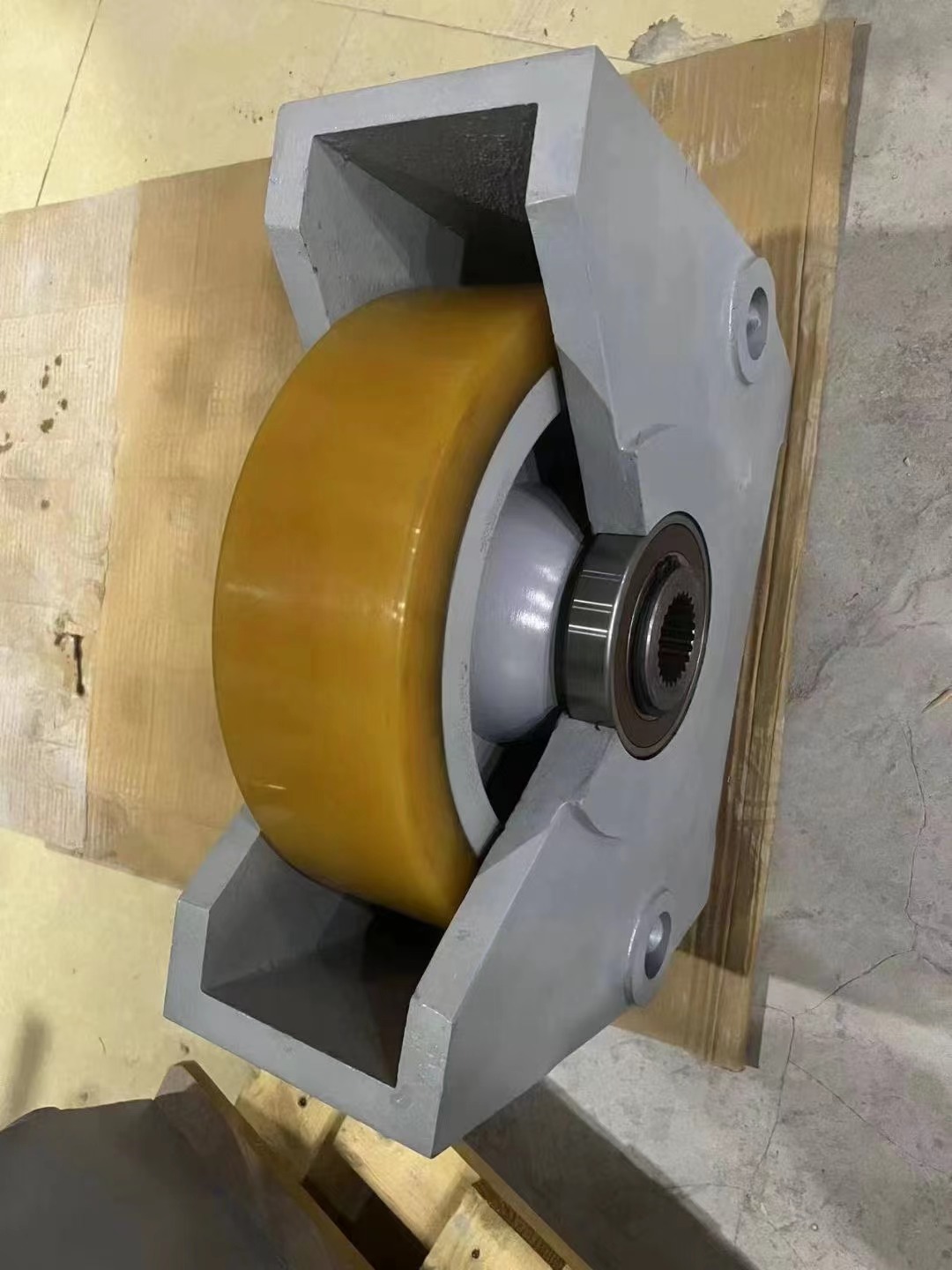

Excellent wear resistance

Traveling wheels with good wear resistance can operate stably for a long time, reduce downtime and maintenance time due to wear, and improve the overall operating efficiency of the warehousing system. In order to improve the wear resistance of the running wheels, they are usually made of wear-resistant materials, such as high-strength alloy steel, polyurethane, etc. These materials have excellent anti-wear properties and can maintain a long service life in harsh working environments.

High load bearing capacity

The load-bearing capacity of the warehouse stacker's traveling wheels refers to the maximum load it can bear. The traveling wheels with strong load-bearing capacity can ensure the stable operation of the stacker under heavy load conditions and avoid safety accidents caused by overload. When selecting the traveling wheels, it is necessary to select according to the actual load requirements of the stacker to ensure that the load-bearing capacity of the traveling wheels can meet the actual needs.

Product features

● Reasonable structural design is adopted to enable the wheel hub, spokes, rim and other parts to give full play to their performance advantages. Reasonable structural design can ensure the stable operation of the running wheel under high-speed and heavy-load conditions and reduce failures and damage caused by structural problems.

● Made of wear-resistant materials, it has excellent anti-wear properties. This enables the running wheel to maintain a lower wear rate and extend its service life under long-term, high-frequency working conditions.

● The traveling wheels with strong load-bearing capacity can ensure the stable operation of the stacker under heavy load conditions and avoid safety accidents caused by overload.

● It has good stability and can maintain smooth operation in various complex working environments. Travel wheels with good stability can reduce failures and damage caused by vibration, impact and other factors, and improve the overall operating efficiency of the warehousing system.

● The modular design makes replacement and maintenance more convenient and faster. When the running wheels fail or wear out, they can be quickly replaced with new ones, reducing downtime for maintenance and improving the overall operating efficiency of the warehousing system.

How to replace the traveling wheels of a stacker

● Before replacing the traveling wheels of the warehouse stacker, you need to prepare the corresponding tools, such as wrenches, screwdrivers, jacks, etc. Make sure these tools are complete and in good condition so that the replacement job can be completed smoothly.

● Use a tool such as a wrench or screwdriver to remove the old running wheels from the stacker. During the disassembly process, you need to pay attention to safe operation to avoid damage to the stacker or personal injury.

● Install the new traveling wheel on the stacker, ensuring that the installation position is correct and the installation is secure. During the installation process, attention needs to be paid to the lubrication and sealing performance of the bearings to ensure that the running wheels can operate normally.

● After the installation is completed, the running wheels need to be inspected and debugged. Check whether the running wheel is firmly installed and whether the bearing is well lubricated, etc. During the debugging process, it is necessary to observe the running status of the walking wheel to ensure that it can run smoothly and stably.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China