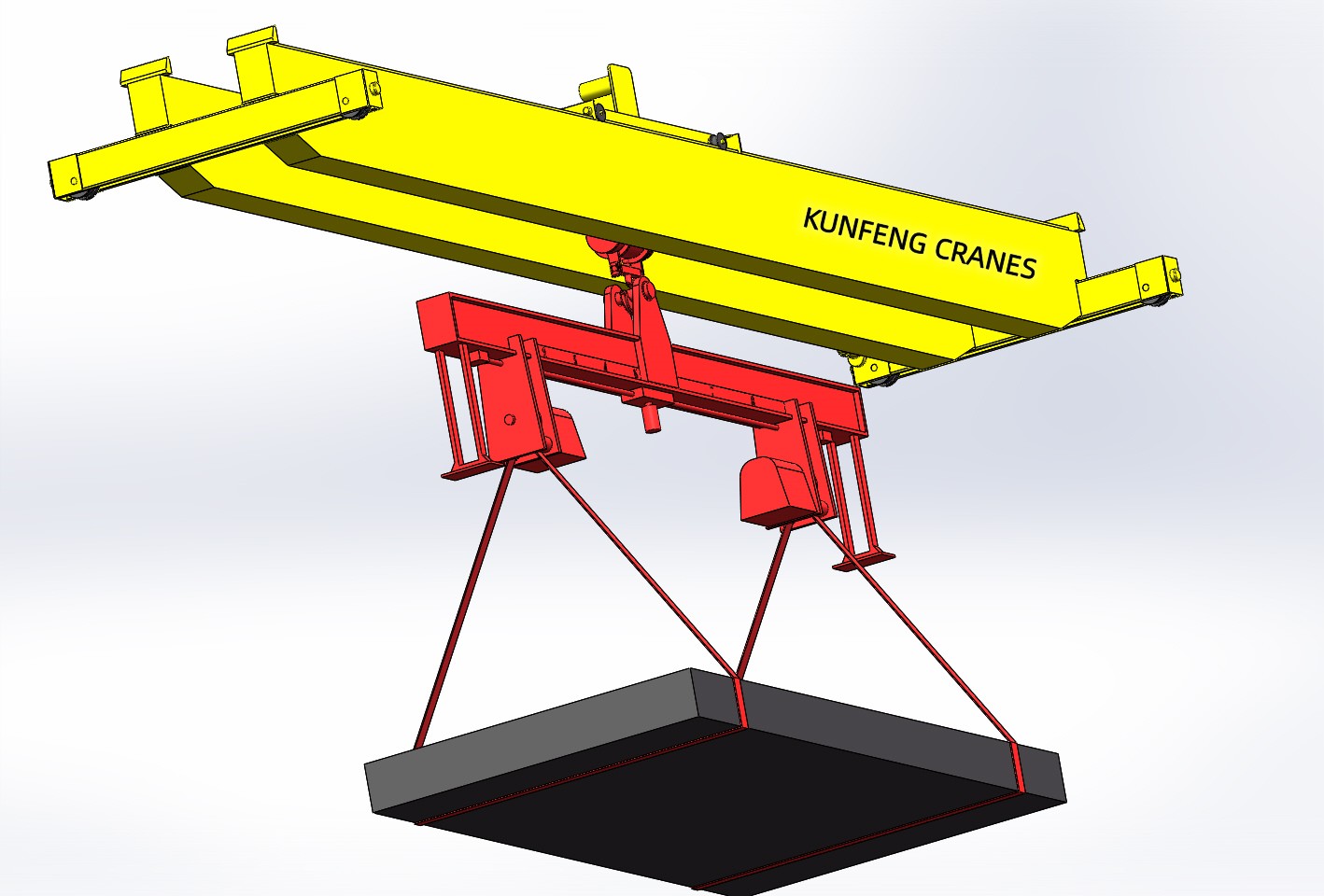

| Load Turning Device for Crane

| Want to know more about Load Turning Device for Crane?

Load turning device for crane is specially designed for heavy workpieces and special-shaped objects in the industrial field. It can realize precise 90°, 180° or any angle turning.

The load turning device for crane is designed for heavy workpieces and special-shaped objects in the industrial field, and can achieve precise 90°, 180° or any angle flipping. The device is equipped with advanced electric, hydraulic or pneumatic drive systems to ensure smooth and efficient flipping to meet the needs of different working conditions. Its high load capacity, intelligent control, and safety protection functions (such as anti-slip, overload protection and limit devices) make operation safer and more reliable. The equipment has a sturdy and durable structure and is easy to maintain. It is widely used in metal processing, mold manufacturing, automobile manufacturing and other industries. It is an ideal choice for improving production efficiency and operation safety.

The load turning device for crane is installed through the fixed connector (such as a hanging ring or a pin hook) between the hook and the turning device, and the turning device is firmly connected to the crane's sling system. During installation, the turning device and the hook are precisely docked to ensure that the device can stably carry the load and run smoothly. The entire installation process requires ensuring a firm connection and accurate position, and making necessary adjustments according to the weight and type of the workpiece to ensure the safety and efficiency of the flipping operation.

Advantages of load turning device

● By accurately controlling the flipping angle and speed, the workpiece can be flipped quickly and stably.

● Equipped with anti-slip device, overload protection and limit device to ensure that the workpiece remains stable during the turning process.

● Using high-strength materials and powerful drive system, it can withstand the turning needs of heavy workpieces.

● It is compatible with various types of crane systems (bridge, gantry, etc.), suitable for turning workpieces of different sizes and shapes.

● The design structure is compact, occupies a small space, is easy to install and maintain, and is especially suitable for working environments with limited space.

● The fixture, load capacity, turning angle, etc. can be customized according to customer needs.

Load turning device for crane can operate stably in high-load and high-frequency operation environments, and adapt to various workpiece types (including heavy, irregularly shaped or easily deformed workpieces). Turning device is used in conjunction with the crane system to achieve accurate and smooth turning movements in complex working environments, while ensuring safety and efficiency during operation.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China