| 180 Deg Hanging Load Turning Machine

| Want to know more about 180 Deg Hanging Load Turning Machine?

Structure, capacity and applications of load turning machine vary a lot. Chains are recommended for capacities over 20 tons and high temperature surfaces. They are more suitable than polyester belts in harsh environments.

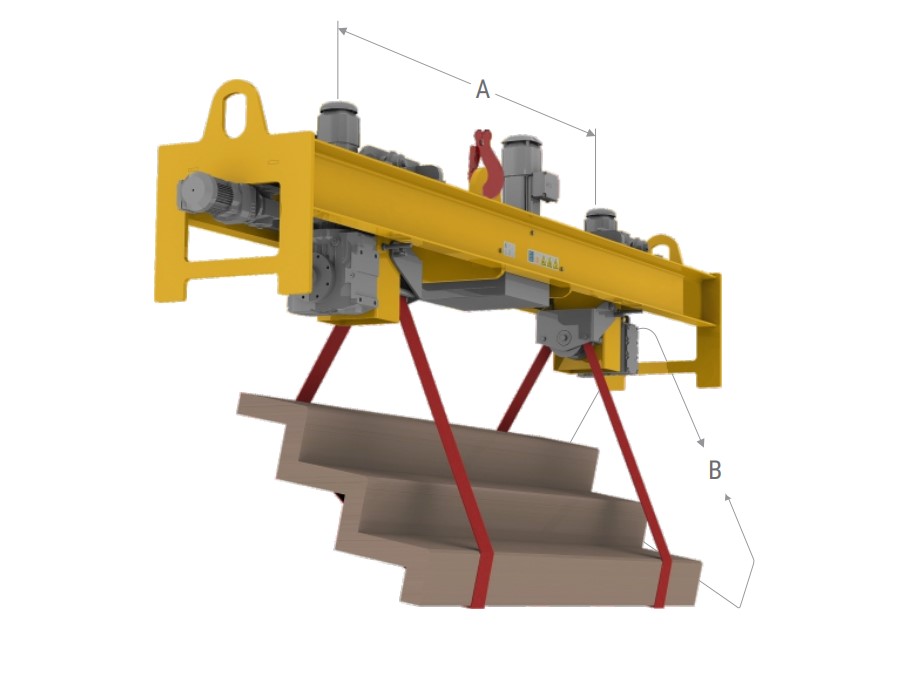

Load turning machine, which refers to beam rotator, turnover spreader, is a mechanical equipment used to rotate heavy objects, such as steel plates or large components, for easier access, manipulation, or processing during manufacturing and repair operations. It facilitates efficient and safe handling in various industries, especially in steel structure process.

Turning heavy duty loads is often a difficult and dangerous task. Thanks to the load turning device, it helps move and turn heavy objects more safely. Equipped with double girders hoist, carriages and motors, load turning machine is easy to meet your specific requirements. There are three major types of load turning machines, including chain rotator, belt rotator and the chain belt rotator.

• Different load turning machines vary a lot, as in the construction:

Load turning machines come in different types and have varying capacities based on their construction.

For lifting lighter goods, electric powered load-turning units are suitable. Load turning units can be operated separately. Besides, when it comes to lifting irregular goods, load turning units coordinate with each other, ensuring safe operation. These units have a capacity of up to 80 tons when operated synchronously.

Beam rotator has a compact design and excels in rotating heavy loads. It makes the rotation of structural steel safer and easier.

To start rotating, you simply need to suspend the load turning units to your cranes or hoist hooks.

• Difference in capacity:

When in units, the load turning capacity can up to 20 ton. With grade 80 load chain, the chain load turning device is stronger than the belt load turning device.

• Difference for products:

Compared with belt rotator, chain load beam is more likely to damage products surface. While polyester fabric are more suitable for sensitive loads turning.

Chains are recommended for capacities over 20 tons and high temperature surfaces. They are more suitable than polyester belts in harsh environments.

Belts are elastic, flexible, lightweight, and perfectly suitable for sensitive surfaces. However, it's important to note that edge and belt protectors are required when dealing with sharp-edged parts. Additionally, if you need to rotate irregular objects, a polyester belt is also a good option.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China