| Advantages of Clean Room Jib Crane for Semiconductor Workshop

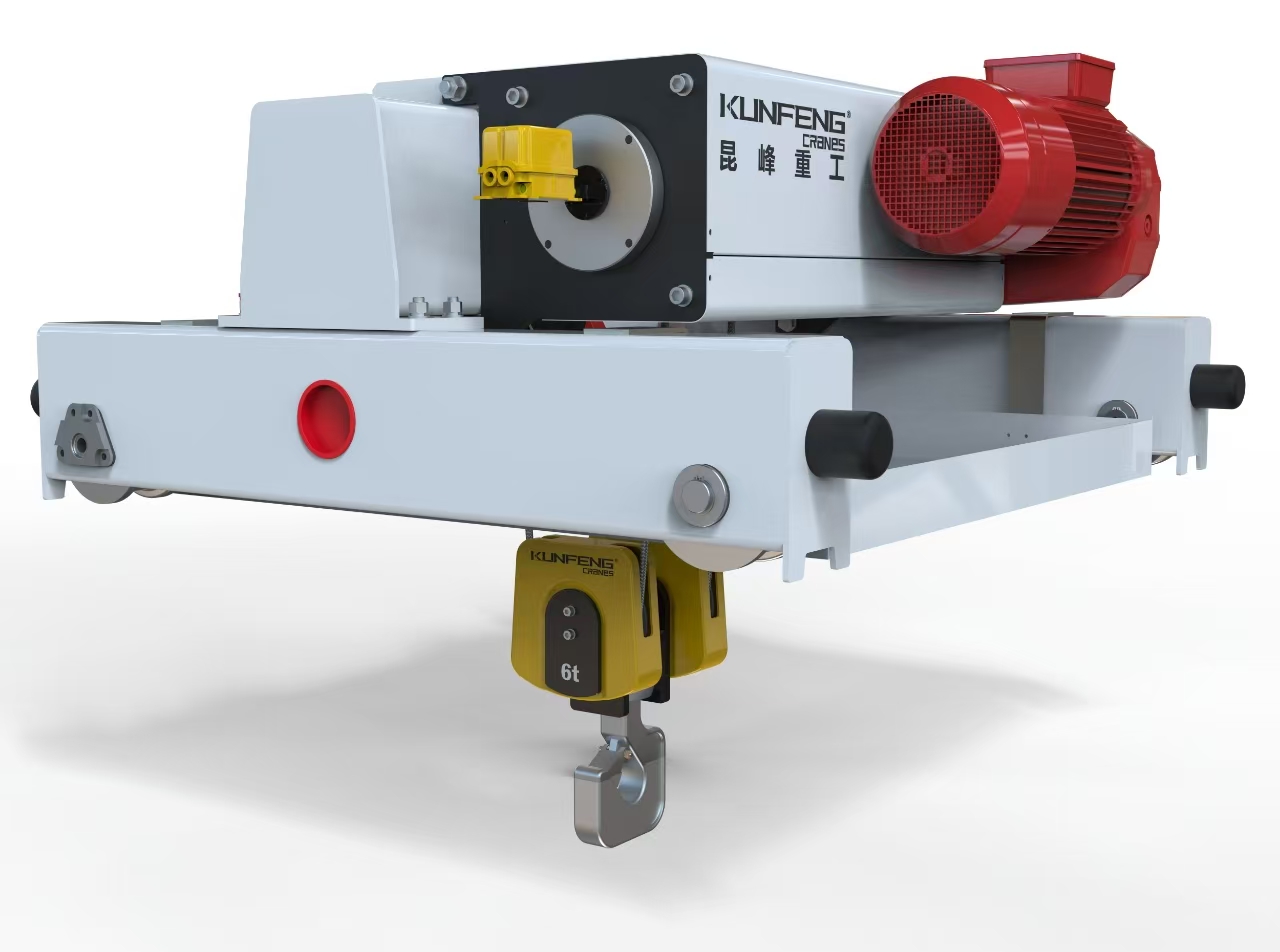

Clean room jib crane is a kind of lifting equipment installed in a clean room, mainly used for handling and lifting of materials. It consists of a column, a swing arm, a rotary drive device and an electric hoist. The lower end of the column is fixed on the concrete foundation through anchor bolts, and the swing arm is driven to rotate by a cycloidal pinwheel reduction device. The electric hoist is hung on the I-beam of the swing arm and can run left and right in a straight line and lift heavy objects.

In semiconductor production workshops, clean room jib cranes are mainly used to transport high-precision, high-cleanliness materials such as wafers and various components. Since semiconductor production has extremely high requirements for environmental cleanliness, during the design and manufacturing process of clean room jib cranes, special attention is paid to preventing the fall of dust, oil and other contaminants to ensure the cleanliness of the production environment.

Advantages of clean room jib cranes

1. The structural design fully considers the special needs of the semiconductor production workshop, and has the characteristics of novel, reasonable and simple structure. This not only makes the installation and maintenance of the crane more convenient and faster, but also improves the stability and reliability of the crane.

2. Using electric control, the operation is simple and convenient. At the same time, the rotary drive device of the swing arm adopts a cycloidal pinwheel deceleration device, which makes the rotation of the swing arm more flexible and can meet the needs of material handling at different angles.

3. The swing arm is a hollow steel structure with light weight, large span and large lifting capacity. This allows the crane to cover a larger space during operation and meet the material handling needs of different locations. At the same time, the crane has a large lifting capacity and can meet the needs of handling heavier materials.

4. Use high-quality materials and manufacturing processes to ensure the crane is economical and durable. At the same time, the structural design of the crane also fully considers the convenience of maintenance, making the maintenance process more convenient and faster.

5. The electric drive method is more energy-saving and efficient than the traditional hydraulic or pneumatic drive method. At the same time, the electric drive method also reduces environmental pollution and is in line with the development trend of low-carbon and environmental protection.

Clean room jib cranes not only improve the efficiency and cleanliness in the semiconductor production process, but also provide strong support for the rapid development of the semiconductor industry. In the future, with the continuous development of the semiconductor industry, clean room jib cranes will be more widely used and promoted.