| NDI Monorail Crane Wheels

| Want to know more about NDI Monorail Crane Wheels?

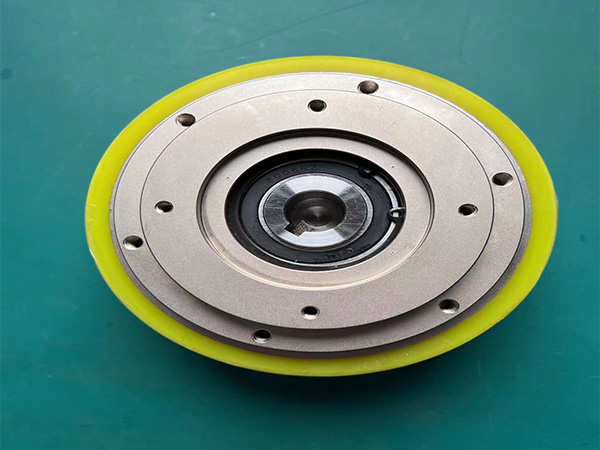

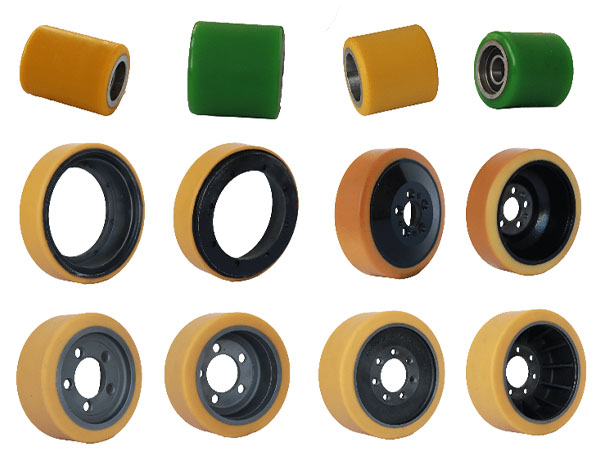

NDI monorail crane wheels are specialized components designed for use in monorail crane systems, which are crucial in various heavy-duty lifting and transportation applications.

NDI monorail crane wheels are specialized components designed for use in monorail crane systems, which are crucial in various heavy-duty lifting and transportation applications. Here's an in-depth look at the features and benefits of NDI monorail crane wheels:

Material and Construction

Polyurethane (PU): NDI wheels are made from a high-quality polyurethane material, offering excellent wear resistance and tear strength compared to traditional rubber materials.

Elastomer: The wheels are crafted from NDIthane 95 elastomer, a special type of polyurethane elastomer known for its good heat resistance and load-bearing capacity.

Performance Characteristics

High Load Capacity: NDI wheels can bear clamping forces of 8-11 Mpa over extended periods, providing the necessary traction for heavy loads.

Friction Coefficient: The wheels have a friction coefficient of about 0.2-0.45 with the rail, ensuring reliable grip and movement.

Applications

Mining Industry: NDI wheels are certified for use in mining headings, making them suitable for underground mining operations where safety and durability are paramount.

Material Handling: They are ideal for monorail systems used in material handling, especially in environments with heavy loads, such as ports, warehouses, and industrial facilities.

Advantages

Excellent Resistance to Mechanical Wear: The polyurethane material ensures that the wheels maintain their performance even under harsh conditions.

Higher Load-Bearing Capacity: Compared to traditional materials, NDI wheels offer superior strength to support heavy loads.

Good Friction and Traction: The wheels provide reliable traction, essential for smooth and controlled movement along the monorail.

Heat Resistance: NDIthane 95 is resistant to high temperatures, allowing the wheels to perform well in various climates and conditions.

Long Service Life: The durable construction of the wheels contributes to a long operational life, reducing the need for frequent replacements.

Resistance to Wet Slip: The wheels maintain their grip even in wet conditions, enhancing safety and reliability.

Flame Retardant and Antistatic Properties: These features add an extra layer of safety in environments where such hazards may be present.

Effective Braking: The design of the wheels contributes to excellent braking effects, crucial for controlling the speed and stopping of loads in transit.

Design and Safety

Drive Wheel System: The wheels are part of a drive system that ensures efficient and safe operation of the monorail crane.

Safety Considerations: The design of the wheels takes into account the need for safety in operation, including resistance to slippage and compliance with relevant safety standards.

NDI monorail crane wheels represent a significant advancement in material handling technology, particularly for monorail crane systems used in challenging environments. Their combination of durability, load-bearing capacity, and safety features makes them a reliable choice for industries that require heavy-duty transportation solutions. As the demand for efficient and safe material handling increases, NDI wheels are well-positioned to meet these needs and contribute to the overall efficiency and safety of monorail crane operations.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China