| AGV Wheels for Material Handling Equipment

| Want to know more about AGV Wheels for Material Handling Equipment?

AGV wheels are designed for robustness, precision, and reliability, enabling smooth and efficient operation of automated guided vehicles across diverse industrial settings.

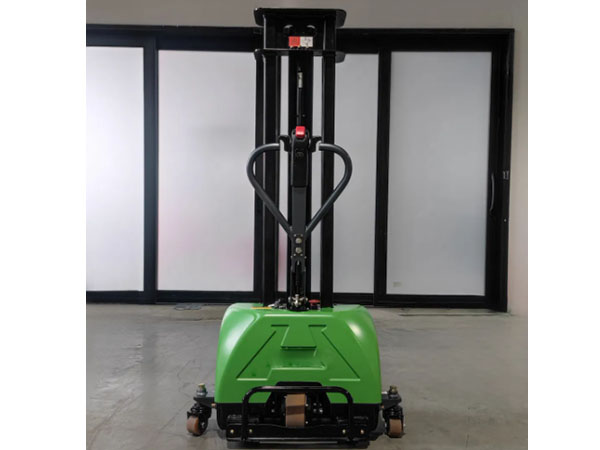

In the rapidly evolving landscape of industrial automation, the role of Automated Guided Vehicles (AGVs) has expanded significantly. At the core of these vehicles lies a critical component: AGV wheels. This article delves into the significance of AGV wheels and how they revolutionize material handling across various industries.

The Importance of AGV Wheels

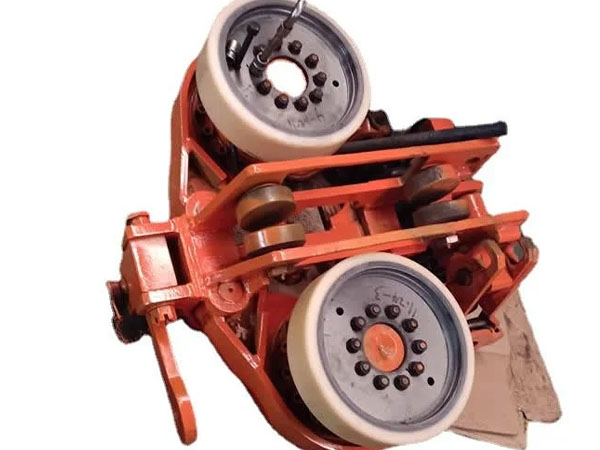

AGV wheels are more than just a means of mobility; they are the lifeline of AGVs, ensuring smooth, efficient, and precise movement within automated systems.

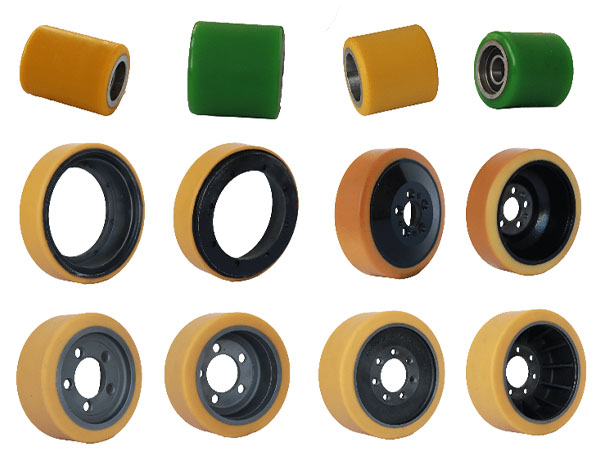

Durability: Constructed from high-quality materials like polyurethane and rubber, AGV wheels are designed to withstand the test of time and the rigors of industrial use.

Load Capacity: With varying load capacities, AGV wheels are tailored to meet the specific demands of different applications, from light to heavy-duty operations.

Low Maintenance: The robustness of AGV wheels means they require minimal maintenance, reducing downtime and operational costs.

Versatility: Suitable for a wide range of surfaces and environments, AGV wheels can be used in manufacturing facilities, warehouses, hospitals, and even outdoor settings.

Advanced Features of AGV Wheels

Noise Reduction: Modern AGV wheels are engineered to operate quietly, making them suitable for noise-sensitive environments.

Friction Control: The design of AGV wheels allows for optimal traction and minimal friction, ensuring smooth movement and reducing wear on both the wheel and the surface.

Safety: Equipped with safety features such as emergency stop mechanisms and collision avoidance sensors, AGV wheels contribute to a safer working environment.

Customization: AGV wheels can be customized to fit specific AGV models and applications, including variations in size, material, and tread pattern.

Applications of AGV Wheels

Warehouse Automation: AGV wheels play a pivotal role in automated storage and retrieval systems, enhancing warehouse efficiency and reducing manual labor.

Manufacturing: In production facilities, AGV wheels enable the seamless transport of materials and products along the assembly line.

Logistics and Distribution: AGVs equipped with specialized wheels facilitate the sorting and dispatch of goods, improving the speed and accuracy of logistics operations.

Healthcare: In hospitals and laboratories, AGV wheels ensure the safe and hygienic transport of medical supplies and samples.

The Future of AGV Wheels

As technology progresses, AGV wheels are expected to incorporate more sophisticated features, such as self-healing tires and energy-harvesting systems. The integration of IoT and AI will enable predictive maintenance and real-time performance optimization.

AGV wheels are the unsung heroes of automated material handling, providing the essential mobility and support for AGVs to function effectively. Their design, durability, and advanced features make them indispensable in today's automated industrial operations. As industries increasingly adopt automation, the role of AGV wheels will only grow in importance, driving the future of material handling towards greater efficiency and intelligence.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China