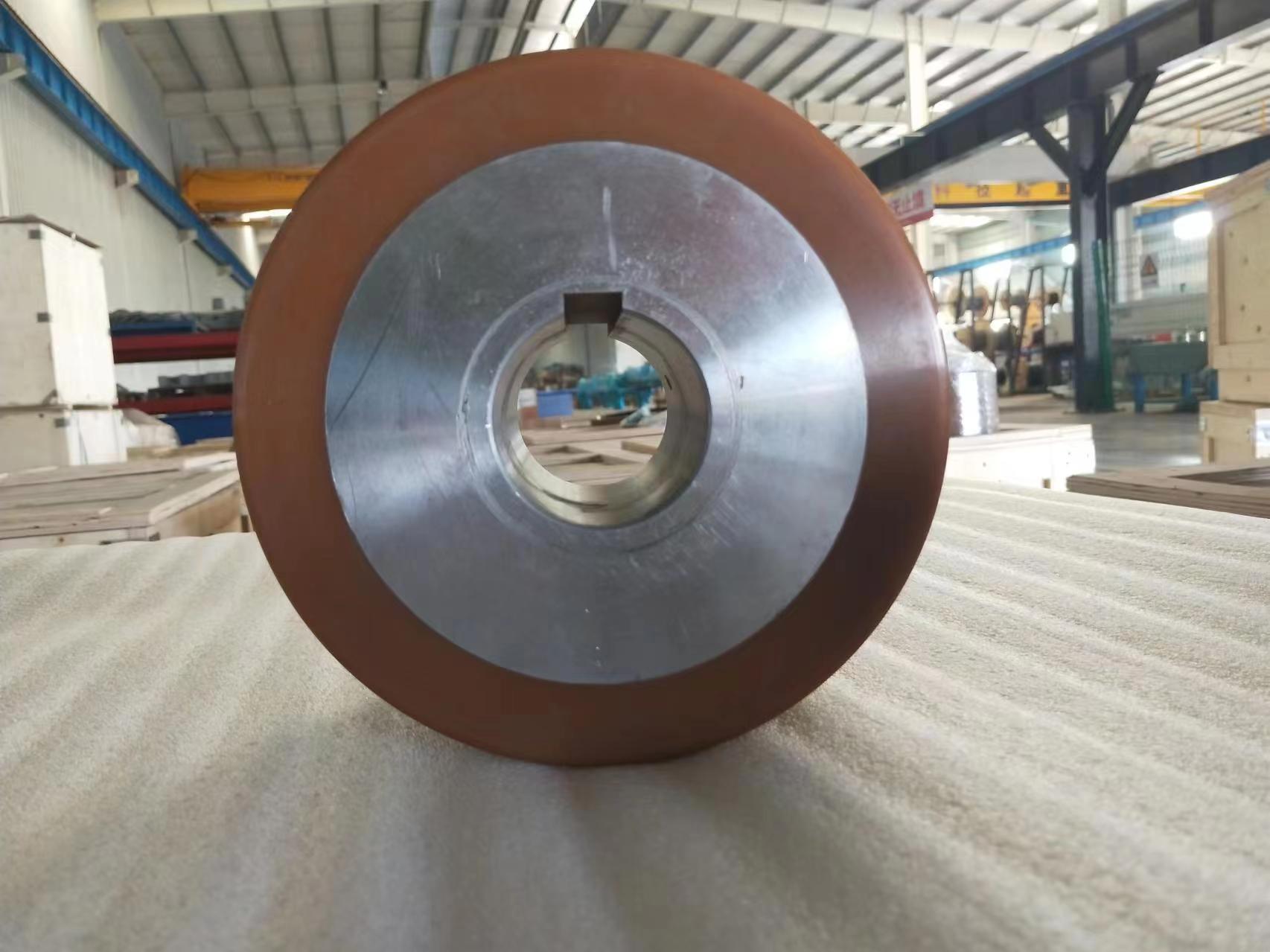

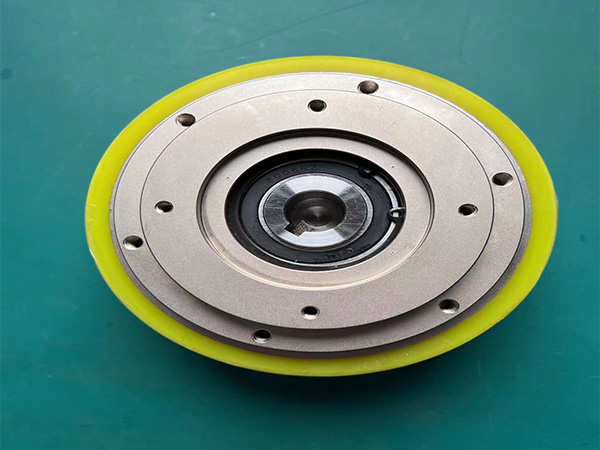

| Polyurethane Coating Aluminum Wheels

| Want to know more about Polyurethane Coating Aluminum Wheels?

Polyurethane coating aluminum wheels are industrial accessories that combine the excellent properties of polyurethane materials with the high-strength properties of aluminum wheel cores.

Polyurethane coating aluminum wheels are industrial accessories that combine the excellent properties of polyurethane materials with the high-strength properties of aluminum wheel cores. Polyurethane (PU) is a polymer material that is widely used in various industrial fields due to its high hardness, high strength, wear resistance, chemical corrosion resistance and other properties. Polyurethane coating aluminum wheels provide reliable support and mobility solutions for a variety of heavy-duty equipment by coating polyurethane material on an aluminum wheel core to form a strong and durable overall structure.

Production process

● Pretreatment: Surface treatment of the aluminum wheel core, including degreasing, rust removal, grinding, etc., to ensure a smooth and clean surface and improve the adhesion of the polyurethane material.

● Primer: Apply a primer on the surface of the clean aluminum wheel core to enhance the adhesion and corrosion resistance of the coating.

● Coating: The polyurethane resin is mixed according to a certain formula and heated to a certain temperature. The polyurethane material is evenly coated on the surface of the aluminum wheel core by spraying or dipping. This step is key to the coating process and ensures that the polyurethane material adheres tightly to the aluminum wheel core.

● Curing: Place the aluminum wheel core coated with polyurethane material in a thermostat or drying room. After a certain period of curing treatment, the polyurethane material is completely dried and solidified to form a solid coating.

● Follow-up treatment: Grinding, polishing and other surface treatments are carried out as needed to improve the surface finish and brightness of the aluminum wheel.

Product features

● Wear resistance: Polyurethane material has high wear resistance, which can effectively reduce wheel wear and extend service life.

● High strength and tear resistance: Polyurethane coating aluminum wheels have high tensile strength and tear resistance, and can maintain structural integrity and stability under heavy loads and complex working conditions.

● Low noise: Polyurethane material has certain shock-absorbing properties, which can effectively reduce the noise generated when the wheels roll.

● Chemical corrosion resistance: Polyurethane materials have good resistance to various chemical substances and can effectively prevent corrosion.

● Anti-static and flame retardant: Polyurethane materials also have good anti-static and flame retardant properties, which improves the safety of use.

● Good grip: Through the coating process, polyurethane coating aluminum wheels can provide better grip, ensuring stable driving on various surfaces.

Usage scenarios

● Logistics industry: used in trolleys, trucks, forklifts and other equipment to provide smooth movement and stable support.

● Industrial manufacturing: Used on various conveyor belts, rollers and other equipment on factory production lines to improve the efficiency of material transportation.

● Warehousing equipment: Used for warehouse shelves, material racks and other equipment to make the transportation of goods more convenient and safer.

● Medical equipment: Due to its corrosion resistance and antibacterial properties, it is suitable for equipment such as operating tables and hospital beds.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China