| Polyurethane Drive Wheel for Warehouse Stacker

| Want to know more about Polyurethane Drive Wheel for Warehouse Stacker?

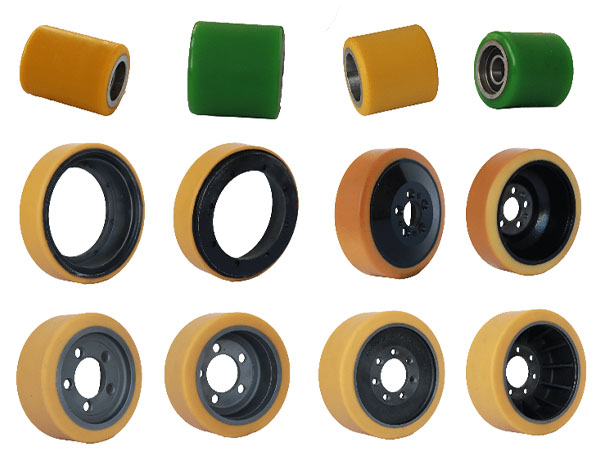

The stacker drive wheel is made of highly wear-resistant polyurethane material, customized with different hardness, wheel diameter and wheel core material, suitable for various types of stackers and warehouse operating environments.

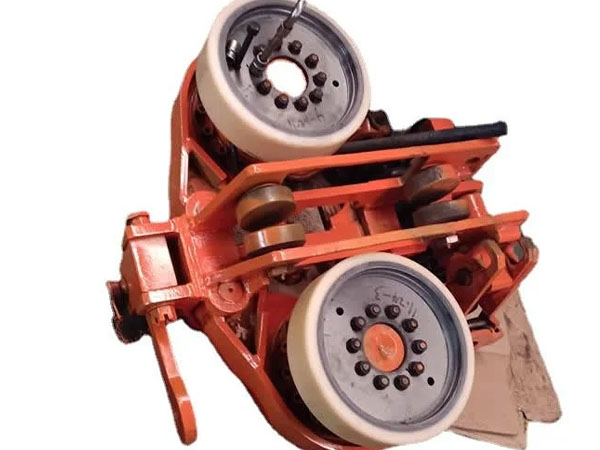

Warehouse stacker is a special crane used for handling and stacking goods in warehouses, workshops and other places. It mainly uses pick-up devices such as forks or skewers to grab, transport and stack unit goods. Stacking cranes are lifting and transportation equipment in warehousing equipment. Their application reduces the labor intensity of workers, improves the utilization rate and turnover rate of the warehouse, and has been widely used in modern logistics and warehousing.

Coating process of stacker wheel

● Cleaning and inspection: Thoroughly clean and inspect the driving wheel to ensure cleanliness and defect-free condition before encapsulation, which is the basis for ensuring coating quality.

● Grinding treatment: Grind the surface of the drive wheel to increase its adhesion with the polyurethane material. This step requires mastering the appropriate degree of sanding, which not only ensures moderate surface roughness, but also avoids surface damage caused by over-sanding.

● Gluing and pasting: Apply special glue evenly on the surface of the drive wheel, and tightly fit the polyurethane material to the drive wheel to ensure no bubbles or wrinkles.

● Curing and trimming: Curing the coated drive wheel to make the polyurethane material closely adhere to the surface of the driving wheel. After curing is complete, trim to remove excess polyurethane material and ensure the surface is flat and smooth.

Characteristics of polyurethane stacker drive wheels

● It can withstand high load and long-term use, ensuring the stable operation of the stacker.

● It has excellent wear resistance and reduces performance degradation and failure rate caused by wear.

● The polyurethane material itself has certain self-lubricating properties, which can reduce friction and wear and improve the operating efficiency and service life of the equipment.

● It can be flexibly adjusted according to different usage environments and needs to meet cargo transportation needs at different heights and angles.

● It has stable support performance to ensure the safety and stability of goods during transportation.

● Able to maintain stable performance in various harsh environments.

Application occasions

● In automated three-dimensional warehouses, equipment needs to be lifted, lowered and moved frequently. The high strength, wear resistance and stability of polyurethane driving wheels can meet these needs.

● In logistics and transportation, equipment needs to withstand greater weight and impact. The high load-bearing capacity and wear resistance of polyurethane driving wheels can provide stable and efficient support.

● In manufacturing, the high wear resistance and stability of polyurethane drive wheels are also suitable for supporting and transporting production equipment.

Contact us now for more product details and quotes to optimize your warehouse handling performance!

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China