| PU Coating Wheels in The Playground Equipment

| Want to know more about PU Coating Wheels in The Playground Equipment?

Polyurethane (PU) coating wheels are widely used in playground equipment due to their exceptional properties that enhance safety, durability, and performance.

Polyurethane (PU) coating wheels are widely used in playground equipment due to their exceptional properties that enhance safety, durability, and performance. These wheels are particularly beneficial in ride-on toys, swing sets, and other moving parts of playground equipment where smooth movement and resistance to wear are crucial.

Key Features of PU Coating Wheels

• Durability: PU coatings are known for their high abrasion resistance, which means the wheels can withstand the rigors of regular use without showing significant signs of wear. This is particularly important in playground environments where equipment is subject to constant movement and occasional impacts.

• Smooth Rolling: The smooth surface of PU coating ensures that wheels roll quietly and smoothly, reducing noise and providing a pleasant experience for children using the equipment.

• Chemical Resistance: Polyurethane coatings are resistant to a variety of chemicals, including cleaning agents and oils, which helps maintain the integrity of the wheels even when exposed to harsh cleaning processes.

• Temperature Stability: PU coatings maintain their properties over a wide range of temperatures, making them suitable for outdoor use in various climates without degrading or becoming brittle.

• Non-marking: Unlike some other materials, PU coating wheels do not leave marks or scuff marks on surfaces, which is beneficial for both outdoor and indoor playgrounds where flooring needs to be kept clean and free of damage.

• Vibration Absorption: The elasticity of PU coatings helps absorb vibrations, providing a more comfortable ride and reducing the impact on the equipment itself, which can extend the lifespan of the entire piece.

Five Advantages of Polyurethane Drive Wheel Doesn't Derail

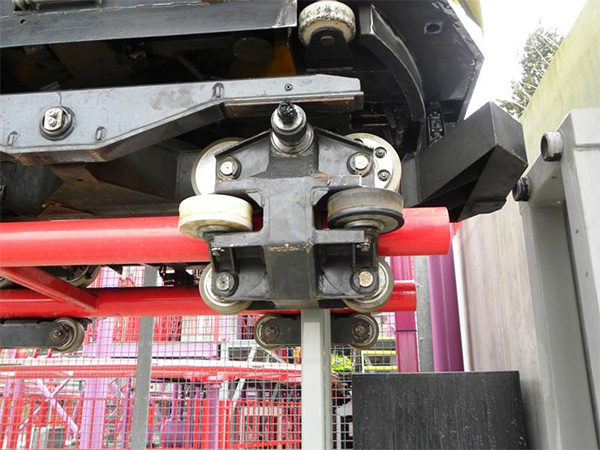

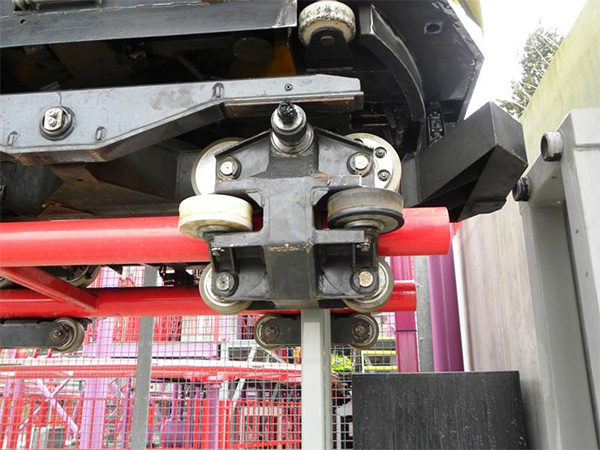

1. Multiwheel System:

•Roller coasters are usually equipped with multiple sets of wheels, including drive wheels, guide wheels and stability wheels. The driving wheel is responsible for pushing the carriage forward; The guide wheel is used to keep the carriage in the correct position on the track; Stability wheels prevent the carriage from rolling over on vertical or inclined tracks.

•These wheels work together to ensure the stability of the roller coaster during its operation, keeping it on track even during the most intense action.

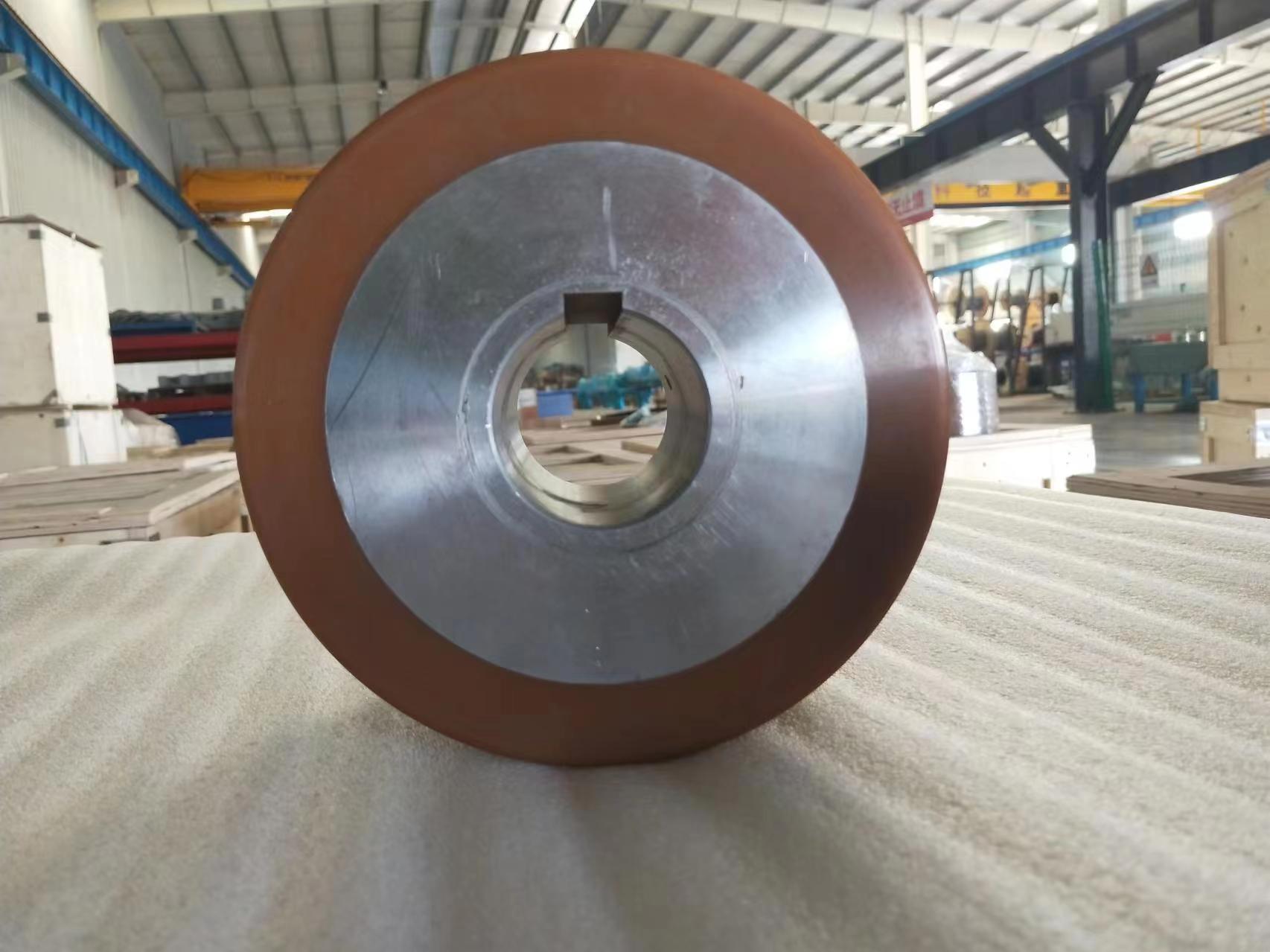

2. PU Material Strength and Durability:

•Wheels are made of materials (steel and polyurethane) with high wear resistance and strength that can withstand prolonged friction and heavy pressure without deformation or damage.

•Polyurethane-coated wheels provide better grip and reduce the risk of skidding on the track.

3. Precision Manufacturing and Installation:

•Both the wheels and the tracks have undergone precision manufacturing and strict tolerance control to ensure a perfect fit between them.

•During installation, both the position and Angle of the wheels need to be precisely adjusted to ensure that they are properly in contact with the track, avoiding any potential problems that could lead to derailment.

4. Regular Maintenance and Inspection:

•Ride equipment, especially roller coasters, receive regular professional maintenance and safety checks, including inspections of wheels and tracks, to ensure they are in good working order and any potential problems are detected and fixed in a timely manner.

Available in many durometers and profiles, our polyurethane wheels can be tailormade to the exact usage. For more specific information on the PU wheels used in the playground equipment, visiting our website.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China