| Polyurethane Coated Travelling Wheel Blocks

| Want to know more about Polyurethane Coated Travelling Wheel Blocks?

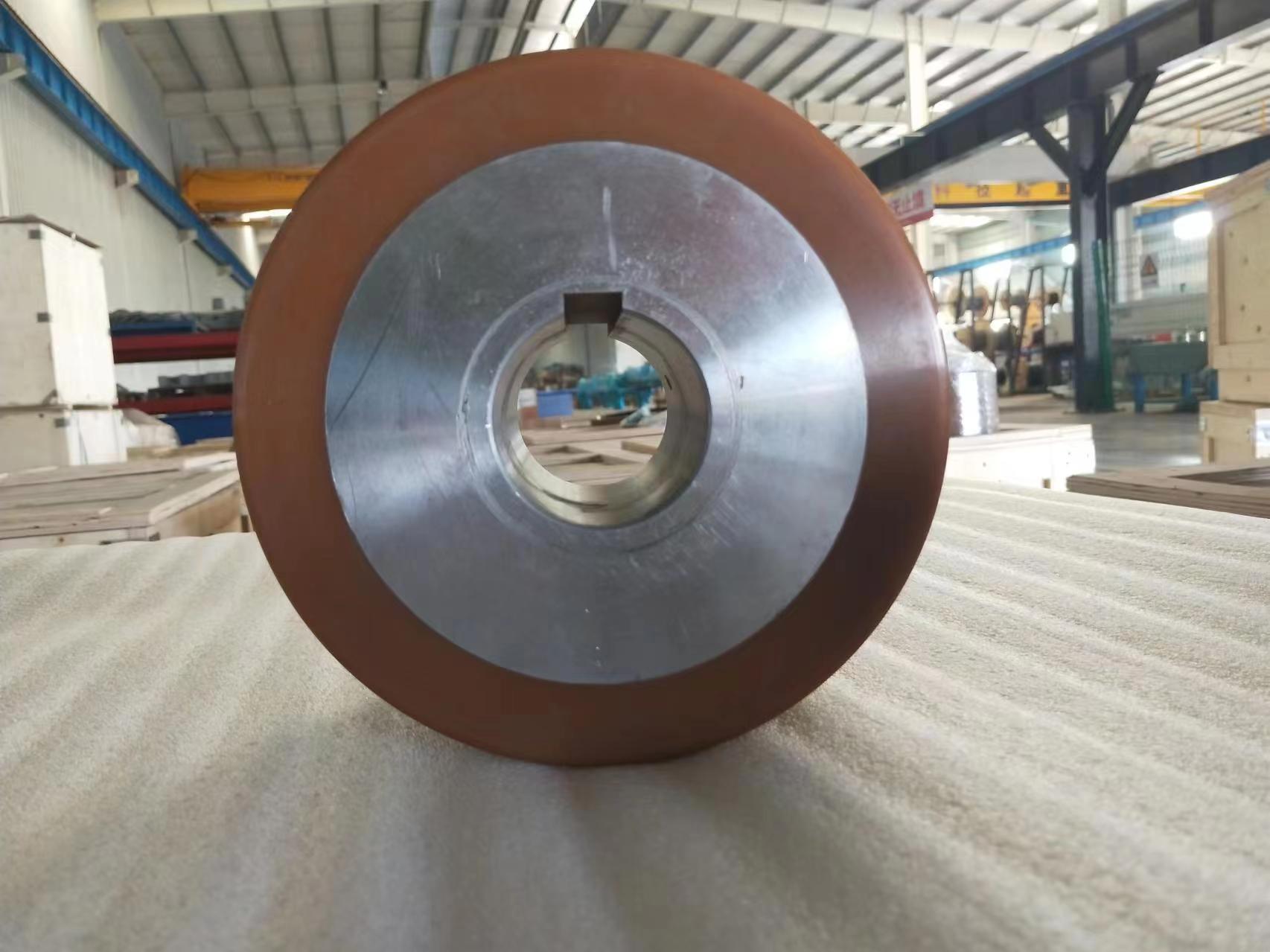

Polyurethane coated travelling wheel block is a composite travelling mechanism that combines the high elasticity and wear resistance of polyurethane material with the strength of metal structure.

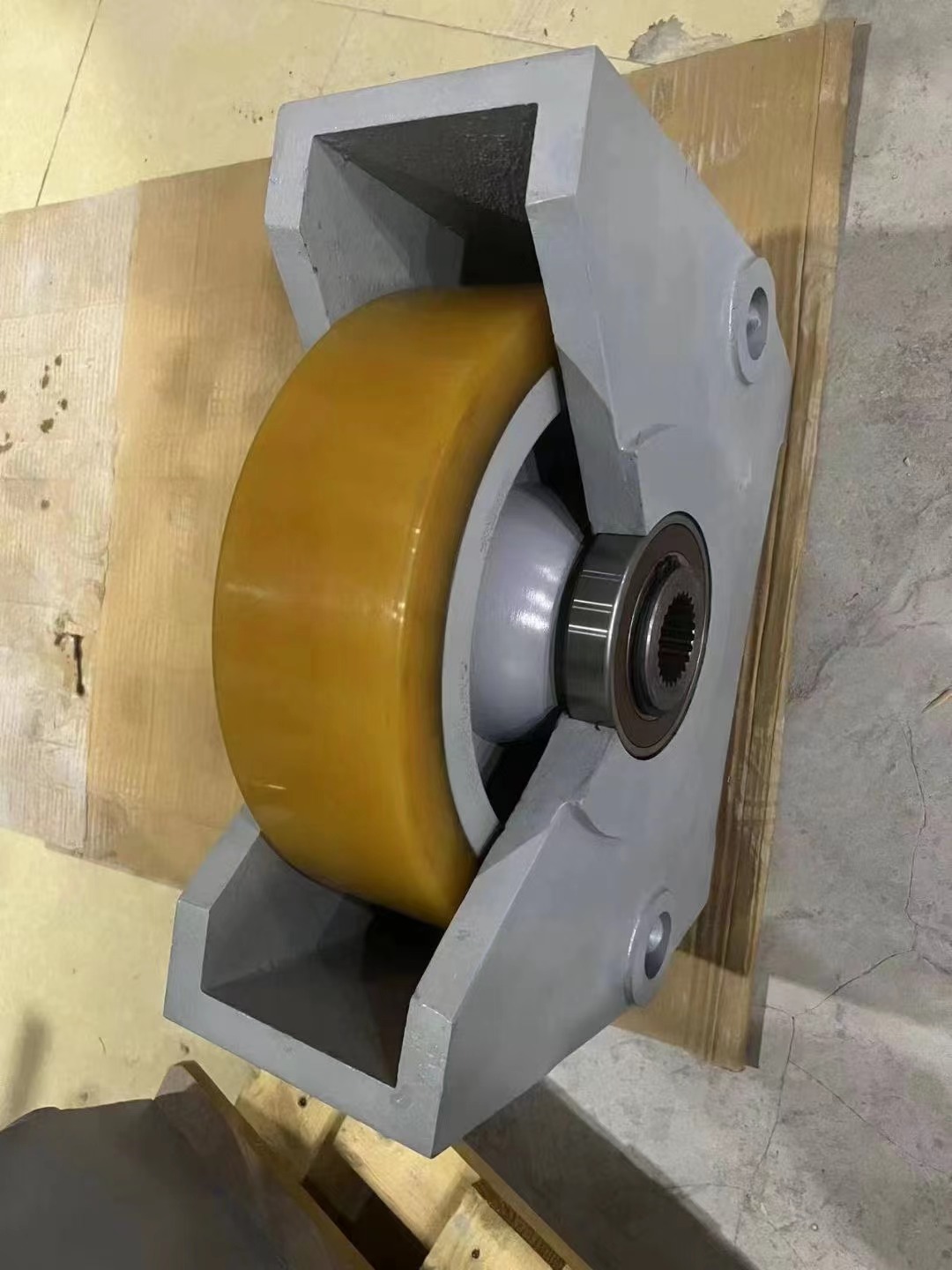

Polyurethane coated travelling wheel block is a composite travelling mechanism that combines the high elasticity and wear resistance of polyurethane material with the strength of metal structure. It usually consists of polyurethane-coated travelling wheel blocks, shafts, bearings, bearing boxes and other components, and is used to support and drive various mechanical equipment to move on tracks or on the ground. This kind of traveling wheel block is widely used in cranes, stackers, automated production lines and other occasions to provide stable and efficient movement performance for the equipment.

The production process of polyurethane coated walking wheel blocks mainly includes the following steps:

Wheel core treatment:

● Cleaning: Clean the old and new wheel cores to remove surface oil, impurities or old coating residues.

● Roughening treatment: roughen the surface of the wheel core to increase the bonding area and strength between the polyurethane coating and the wheel core.

Polyurethane coating:

● According to the design requirements, select the appropriate polyurethane material.

● The polyurethane material is coated on the wheel core using a hot press molding or injection molding process to form a travelling wheel with high elasticity and wear resistance.

Vulcanization treatment:

● After the coating is completed, a long vulcanization process is performed to ensure a strong bond between the polyurethane coating and the wheel core.

Assembly and debugging:

● Assemble the coated travelling wheel with shafts, bearings, bearing boxes and other components.

● Carry out necessary debugging and testing to ensure that the performance of the traveling wheel box meets the design requirements.

Design features

● High load-bearing capacity: The polyurethane-coated traveling wheel has high mechanical strength and load-bearing capacity, and can support and drive heavy mechanical equipment.

● Good wear resistance: Polyurethane material has excellent wear resistance, which can extend the service life of the walking wheel and reduce replacement frequency and cost.

● Good elasticity: Polyurethane material has good elasticity and can absorb and buffer shock and vibration during walking, protecting equipment and goods from damage.

● Good anti-skid performance: The surface of the travelling wheel is usually designed with anti-skid texture to increase the friction with the ground and improve walking stability.

● Strong customizability: According to different application scenarios and needs, polyurethane-coated walking wheel blocks of different specifications, shapes and hardness can be customized.

Usage scenarios

● Logistics industry: Used in logistics equipment such as trucks, forklifts, and stackers to improve the equipment's operating efficiency and handling capacity.

● Warehousing industry: Used on warehouse shelves, material racks and other equipment to ensure stability during the storage and handling of goods.

● Hoisting machinery: As a key component of the crane's traveling mechanism, it supports the load of the crane and travels repeatedly on the track.

● Automated production line: Used in automated equipment such as robots and conveyor belts to improve the operating efficiency and stability of the equipment.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China