| 285x100 Jungheinrich Forklift Wheels

| Want to know more about 285x100 Jungheinrich Forklift Wheels?

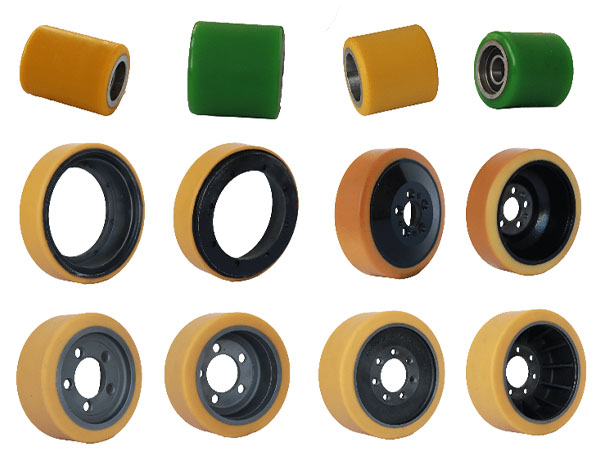

Jungheinrich is a renowned manufacturer of forklifts and material handling equipment. The 285x100 specification refers to the size of the wheels used on some of their forklift models.

Jungheinrich is a renowned manufacturer of forklifts and material handling equipment. The 285x100 specification refers to the size of the wheels used on some of their forklift models. Here’s a detailed look at these wheels, including their features, applications, and considerations for selection.

Wheel Specifications

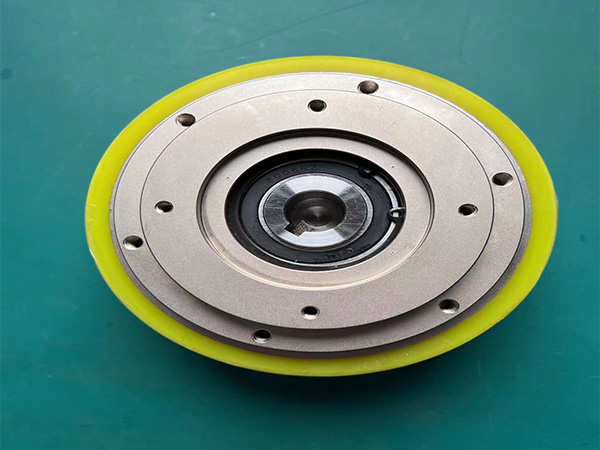

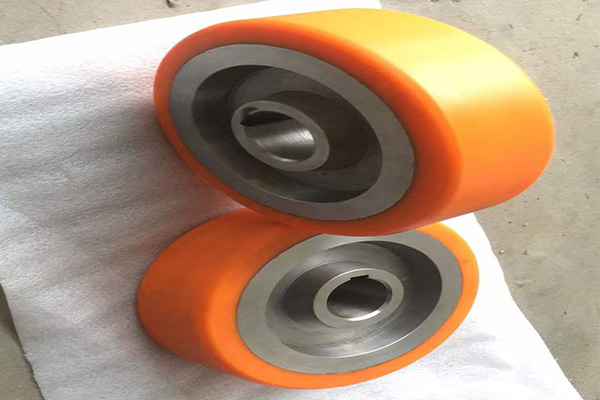

• Dimension: 285mm diameter x 100mm width.

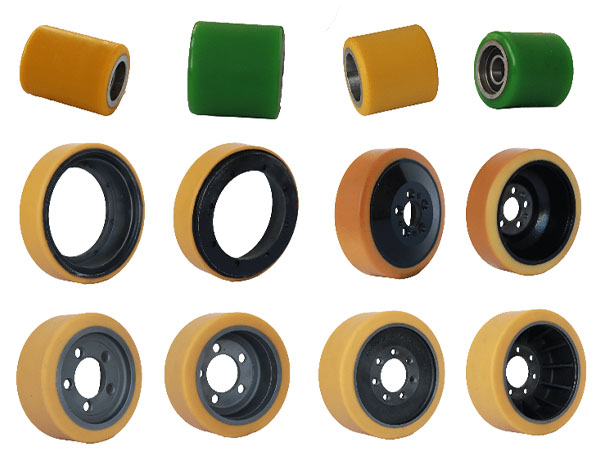

• Material: Typically made of polyurethane, rubber, or a combination of materials.

• Core: May feature a steel core for added strength and durability.

• Tread: Depending on the application, the tread pattern can vary to optimize traction and durability.

Key Features

1. High Elasticity:

• Shock Absorption: The high elasticity of polyurethane helps absorb shocks and vibrations, providing a smoother ride.

• Reduced Fatigue: The cushioning effect reduces operator fatigue by minimizing jolts and vibrations.

2. Durability:

• Wear Resistance: Polyurethane is highly resistant to wear and tear, ensuring longer wheel life.

• Chemical Resistance: Resistant to oils, fuels, and other chemicals commonly found in industrial environments.

3. Low Rolling Resistance:

• Energy Efficiency: Low rolling resistance reduces the energy required to move the forklift, improving overall efficiency.

• Quiet Operation: Reduces noise levels during operation.

4. Temperature Stability:

• Wide Operating Range: Performs well in both cold and hot environments, maintaining its structural integrity.

5. Customizability:

• Size and Shape: Available in various sizes and shapes to fit different forklift models.

• Color Options: Often available in different colors to meet specific needs or for identification purposes.

Applications

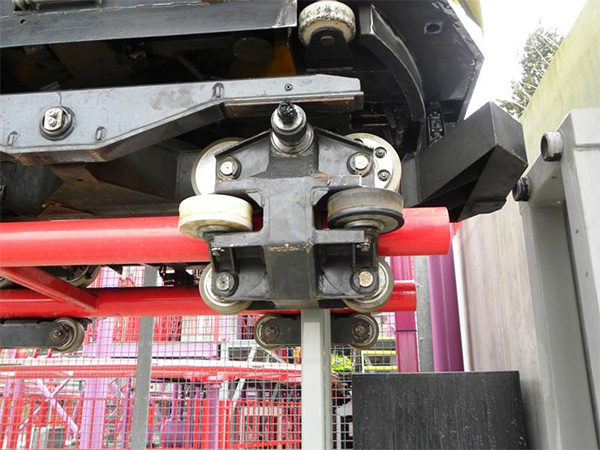

• Warehousing and Logistics: Ideal for moving heavy loads in warehouses and distribution centers.

• Manufacturing Plants: Suitable for use in manufacturing environments where durability and reliability are crucial.

• Outdoor Operations: Resistant to weather conditions, making them suitable for outdoor use.

• Food Processing: Non-marking and easy to clean, making them suitable for food processing facilities.

Installation and Maintenance Tips

• Proper Alignment: Ensure the wheels are properly aligned to avoid uneven wear.

• Regular Inspection: Check for signs of wear or damage regularly.

• Cleaning: Keep the wheels clean to prevent build-up that can affect performance.

• Storage: Store spare wheels in a cool, dry place away from direct sunlight.

The 285x100 Jungheinrich forklift wheels are designed to provide exceptional performance and durability in demanding industrial environments. Their ability to withstand heavy loads, resist wear, and provide a smooth ride enhances the efficiency and safety of forklift operations. By investing in high-quality polyurethane forklift wheels, businesses can improve their operational efficiency and reduce maintenance costs.

If you are looking for 285x100 wheels for your Jungheinrich forklift, it is recommended to consult the KUNFENG cranes manufacturer’s specifications or contact an authorized dealer to ensure compatibility and optimal performance.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China

sale@kfqizhongji.com

Contact

+86 (512) 55 000 225

Phone: +86 177 2978 0576

WhatsApp: +86 13390692151