| Belt Electric Suspension Load Turning Device

| Want to know more about Belt Electric Suspension Load Turning Device?

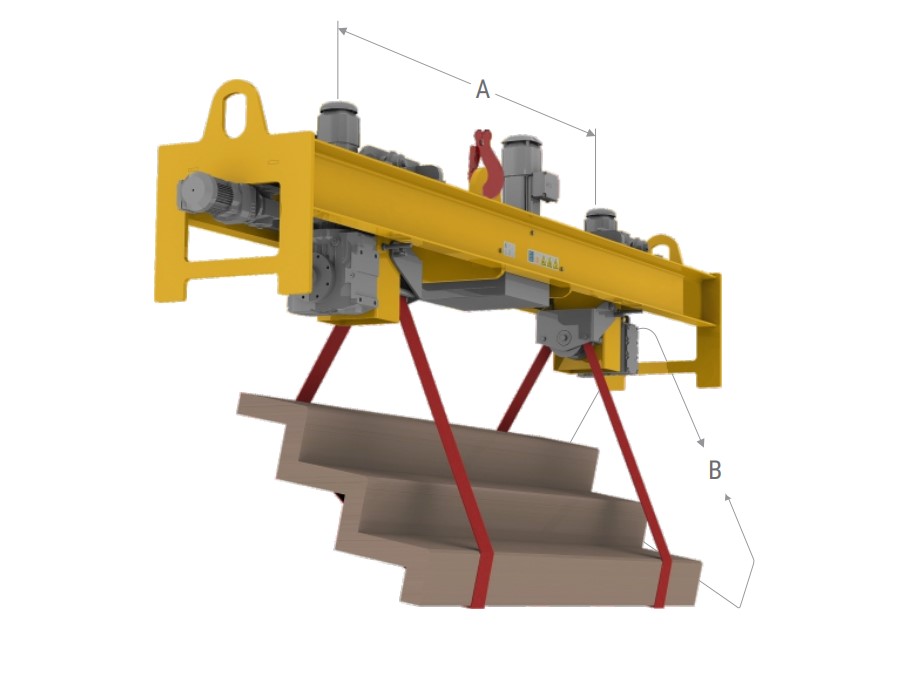

The belt electric suspension load turning device is a special equipment used for handling and flipping goods. It usually consists of a conveyor belt system, suspension device, turning mechanism and co

The belt electric suspension load turning device is a special equipment used for handling and flipping goods. It usually consists of a conveyor belt system, suspension device, turning mechanism and control system. The conveyor belt system is used to carry goods, the suspension device is used to hang goods, the turning mechanism is used to turn goods, and the control system is used to monitor and regulate the operation of the entire equipment. This kind of equipment is widely used in automobile manufacturing, metal processing, logistics sorting and other industries to improve production efficiency and achieve specific production process requirements.

Component:

● Conveyor system: This is the basic part of the equipment used to move goods. Conveyor belts are usually made of wear-resistant rubber or plastic and are driven by electric motors that move along set tracks or guides.

● Suspension device: Suspension device is usually located under the conveyor belt and is used to hang goods. This section usually includes one or more suspension points that can be adjusted as needed to accommodate cargo of different sizes and weights.

● Turning mechanism: The turning mechanism is usually located above the conveyor belt and is used to realize the turning operation of goods. It usually includes one or more turning devices and electric drive devices, which can turn suspended goods to achieve specific production or processing needs.

● Control system: Equipment is usually equipped with a control system to control the movement of the conveyor belt, the position adjustment of the suspension device, and the operation of the turning mechanism to achieve precise control of the goods.

Performance analysis:

● Load Capacity: This refers to the maximum weight the device can carry. Carrying capacity is an important indicator for evaluating the scope of application of equipment. It needs to take into account the design of the suspension device and turning mechanism to ensure that the equipment can safely and stably carry and turn goods.

● Turning speed and accuracy: The performance of the turning mechanism includes turning speed and turning accuracy. The turning speed needs to be high enough to meet the requirements of the production line, and the turning accuracy needs to ensure that the goods are not damaged during the turning process.

● Conveyor speed and adjustment range: The performance of the conveyor belt system includes the speed and adjustment range of the conveyor belt. The conveyor speed needs to be able to adapt to different production needs, while the adjustment range needs to be flexible enough to accommodate goods of different sizes and shapes.

● Safety: The safety performance of the equipment is crucial. This includes the design of safety protection devices, the setting of emergency stop systems, and the guarantee of the stability and safety of suspended goods.

● Energy consumption and efficiency: Evaluate the energy consumption and efficiency of the equipment, including the energy efficiency ratio of the electric motor, the loss of the transmission system, and the intelligence of the control system to ensure that the equipment can be as energy-saving and efficient as possible during operation.

● Maintenance and maintenance: Consider the maintenance and upkeep needs of the equipment, including the fragility of parts, maintenance cycles and maintenance costs, to ensure long-term stable operation of the equipment.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China