| Load Turning Device for Handling Sand Moulding Boxes

| Want to know more about Load Turning Device for Handling Sand Moulding Boxes?

Sand molding boxes load turning device is an automated device used to transport and turn sand molding boxes (common in the foundry industry).

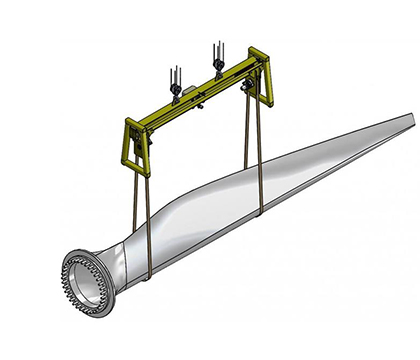

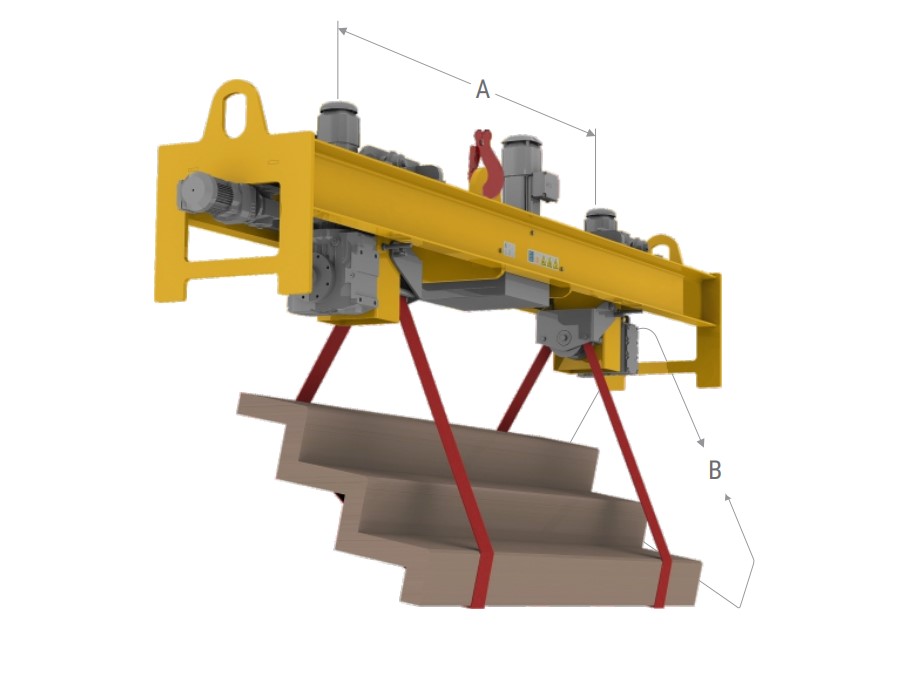

Sand molding boxes load turning device is an automated device used to transport and turn sand molding boxes (common in the foundry industry). It is widely used in casting workshops to help achieve quick and safe flipping of the sand box, so as to facilitate dumping of molten metal in the sand box, closing the sand box, spraying and other operations. Turnover machines are available in various designs, including chain suspended electric load turning devices and belt-suspended electric load turning devices, to accommodate sand molding boxes of different sizes and weights.

Implementation principle

● Conveying and positioning: Move the sand box to the turning area through a conveying system (such as a conveyor belt or crane) and position it accurately.

● Clamping and fixing: The clamping device (such as claws or clamps) in the turning mechanism clamps and fixes the sand box to prevent the sand box from sliding or falling during the turning process.

● Turning operation: start the turning device, drive the turning frame or rotating mechanism through the motor, reducer, chain and other transmission devices to perform the turning operation, so that the sand box can be turned from the upright position to the required angle (such as 180 degrees or 360 degrees).

● Release and movement: After the flipping is completed, the clamping device releases the sand box, and the conveying system restarts to move the flipped sand box to the next work area.

Composition structure

● Base: The support foundation of the load turning device, usually using a solid steel structure to ensure the stability and safety of the device.

● Fixing frame: A component used to fix the sand box. The structure is usually a pair of height-adjustable beams to accommodate sand boxes of different sizes.

● Turning frame: The core part of the load turning device, consisting of a set of rotatable mechanical arms, with a turning clamp installed on the arm for clamping and turning the sand mold box.

● Transmission device: Including motor, reducer, chain and other components, used to control the movement and flipping action of the flipping frame.

● Control system: Used to control and monitor the entire turning process, including speed adjustment of the conveyor belt, motion control of the turning device, and detection of the position and status of the sand box.

Features

● It has a high degree of automation and can quickly complete the turning operation of the sand box to improve production efficiency.

● It is designed with a clamping device and a stable structure to ensure the stability of the sand box during the turning process and prevent accidents.

● Load turning device can be adjusted and customized according to sand boxes of different sizes and weights to meet diverse production needs.

● The use of remote control or button operation allows operators to stay away from the turning area, reducing labor intensity and improving operating safety.

● The equipment structure design is reasonable, easy to maintain and maintain, and reduces maintenance costs.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China