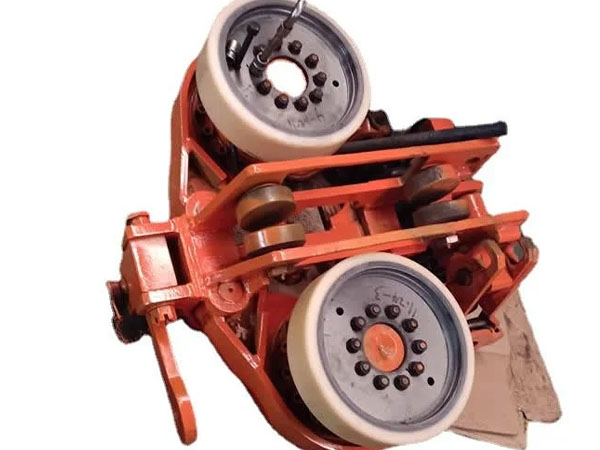

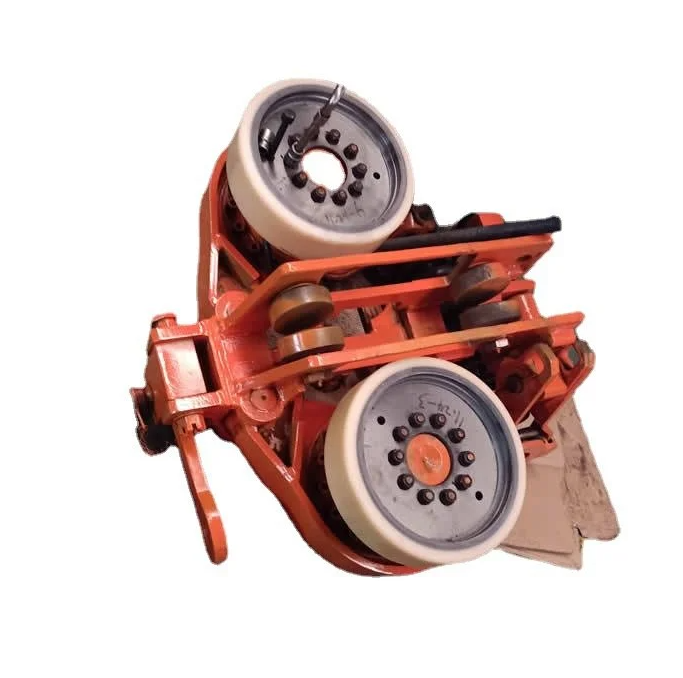

| Friction Drive Wheels for Mining Monorail Crane

| Want to know more about Friction Drive Wheels for Mining Monorail Crane?

Friction drive wheels are a critical component in the operation of mining equipment and monorail cranes, which are specifically designed to provide reliable and efficient traction.

Friction drive wheels are a critical component in the operation of mining equipment and monorail cranes, serving as the primary interface between the moving machinery and the track or rail. These wheels are specifically designed to provide reliable and efficient traction, ensuring smooth and controlled movement in demanding industrial environments.

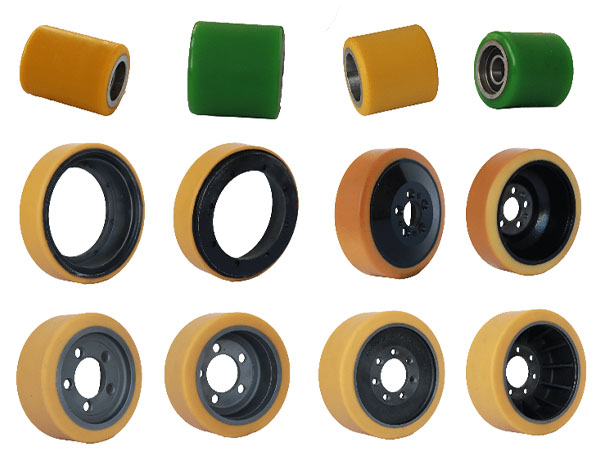

Friction Drive Wheels Material and Spec

Friction drive wheels for monorail transport systems are made of NDIthane 95 elastomer,which is one special polyurethane elastomer with good heat resistance and load-bearing capacity. The normal wheel diameters are 340mm,350mm, 355mm, 360mm, 400mm. The coefficiency of friction between the wheel and rail is about 0.2-0.45.

Key Features of Friction Drive Wheels

• Excellent resistance to mechanical wearing

• Higher load-bearing capacity

• Good friction and traction

• Good heat resistance

• Long run

• Resistance to wet slip

• Flame retardant and Antistatic.

• Excellent braking effect

Applications in Mining

In mining operations, friction drive wheels are integral to the functionality of underground and surface mining equipment.They are used in:

• Conveyor Systems: Ensuring reliable material transport over long distances and varied terrain.

• Haul Trucks: Providing the necessary traction for heavy loads on steep grades and rough surfaces.

• Excavators and Loaders: Enabling precise maneuvering and stability during excavation and material handling.Applications in Monorail CranesFor monorail cranes, friction drive wheels are essential for:

• Horizontal Movement: Allowing smooth travel along monorails in warehouses, manufacturing plants, and other facilities.

• Vertical Lift: Sometimes used in conjunction with lifting mechanisms to maintain stability during vertical operations.

• Positioning Precision: Ensuring accurate placement of loads, crucial for assembly lines and delicate handling tasks.

Conclusion

Friction drive wheels are indispensable in mining and monorail crane applications, offering a combination of strength, durability, and precision. Their ability to maintain traction under challenging conditions ensures safe, efficient, and reliable operation in industrial settings. Whether in the depths of a mine or in the controlled environment of a manufacturing plant, friction drive wheels play a pivotal role in maintaining the productivity and safety of operations.

Tell Us What You Need

Location

No.19 Industry Park, Dongtai, Jiangsu, China